Say you’re a contract manufacturer of printed circuit boards (PCBs), and your customer just made an engineering change that leaves several through-hole vias open.

If you run it through the wave as is, and solder over the vacant holes, the PCB won’t function properly. How do you keep the project on schedule and within budget?

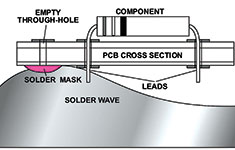

Spot mask, commonly called ‘temporary solder mask’, can be used to protect open through-holes or ‘vias’ in wave soldering (Figure 1). Solder does not wet or stick to it, and it withstands soldering temperatures without charring and bubbling. When you are done, the mask is either peeled off or washed off in your PCB cleaning process.

Why do you need spot mask? PCBs are commonly engineered for a variety of different models, so some areas of the board may be vacant depending on the features of a particular model. That allows for greater economies of scale for bare board production, but can add complexity to the assembly process.

Mask is applied over the open through-holes on a circuit board in the wave soldering process to make sure they stay open. This is necessary because without mask, any contact area on the bottom of the PCB will be fluxed and subsequently soldered. However, solder does not stick to mask, so the area underneath will remain solder-free.

Mask for conformal coating

Another common use for temporary solder mask is to protect contact areas and chemically sensitive components when spraying or dipping conformal coating. Conformal coating is generally electrically insulative, to some degree, so if you coat over a contact area, it will negatively impact its conductivity.

In addition, some components are made of sensitive materials that can be damaged by the harsh solvents used in conformal coating, so need to be protected with spot mask. Electromechanical components with moveable parts also need to be protected.

Solder mask vs. solder resist

While it is often called ‘solder mask’, don’t confuse temporary solder mask with permanent solder mask, also called ‘solder resist’. Temporary solder mask should not be used to repair solder resist. If you need to repair cracks or chips in a PCB’s overcoat, Techspray offers TraceTech Green Overcoat Pen.

Mask vs. Kapton tape and boots

Besides temporary solder mask, polyimide tape (commonly called Kapton tape, a brand of E.I. du Pont de Nemours) or pre-formed silicone masking boots can be used to cover select areas of the circuit board. Polyimide tape is popular because it is readily available and applies quickly, without worrying about cure time. A boot simply snaps onto the area to be masked.

The main advantage of temporary solder mask over these other methods is flexibility. Kapton tape generally comes in rolls or die-cut shapes. Masking boots are preformed, so have to be ordered well ahead of a production run. These solutions work 80% of the time, but there are always those special circumstances that can take you by surprise. That’s where spot mask is a perfect fit.

In addition, adhesive on tape can leave residue behind that can create wetting issues for conformal coating. Boots also need to be cleaned periodically as they are coated with baked-on flux, or discarded.

Techspray WonderMASK temporary solder mask can protect plated through-holes, contacts, pins, posts, terminals and gold fingers during wave soldering. These products provide short-term high-temperature protection from molten solder, and will not leave ionic or corrosive residue. WonderMASK solder masks are available in convenient squeeze bottles for a precision application or in gallons for automated applications.

Common applications for temporary solder mask

If you think of spot mask like liquid masking tape, you can imagine all kinds of creative uses for it. EMS (electronics manufacturing services) process engineers are constantly challenged with meeting the requirements of a wide variety of customers. Solutions often have to be found within tight timelines and within budgets that have been set without all the variables taken into account. Temporary solder mask is an important tool in the process engineer’s toolbox because it can be plugged into a variety of applications to solve immediate assembly problems:

1. Protecting open vias in wave soldering – As mentioned above, this is the most common use for spot mask. To ensure open vias stay open, and not soldered in the wave soldering process, mask is strategically applied. Solder doesn’t wet to mask, so the areas underneath will remain solder-free.

2. Masking conformal coating – When spraying conformal coating onto a PCB or dipping the board into coating, there are often areas that shouldn’t be coated, like contact areas. Conformal coatings are generally electrically insulative, so if you coat over a contact area, it will negatively impact its conductivity. In addition, some components are made of sensitive materials that can be damaged by the harsh solvents used in conformal coating, so may need to be protected with spot mask. This is less of an issue when using a selective spray system, but if applying coating from an aerosol can, through a hand sprayer, or dipping process, masking is often required.

3. Masking around components – SMT (surface mount technology) and BGA (ball grid array) components commonly have very low stand-off areas (the space between the component and the surface of the board). Even when applying conformal coating with a selective spray system, there is a risk of the material wicking under the component through capillary action. Mask can be applied around the component to create a dam.

4. Holding components in place when soldering two-sided boards – When assembling two-sided SMT circuit boards, it can be a challenge to solder components on the bottom side of the board without affecting the components on the top. For the first pass through the reflow oven, gravity holds the components in place as the solder melts and then solidifies. For the second pass through the reflow oven, larger components can have more of a tendency to drop off. Temporary solder mask can be applied to the corners of BGAs and other large components to hold them in place, then the mask is removed at the end of the assembly process.

5. Protecting heat-sensitive components in the reflow process – Mask can provide thermal insulation for heat-sensitive components that must pass through a wave or reflow soldering process. Since temporary solder mask isn’t engineered for this application, manufacturers of the material will probably be of little help qualifying the product.

How to apply temporary solder mask for wave soldering

Spot mask can be hand-applied, dispensed with a pneumatic system, or stencil printed. Each application method has its own advantages, disadvantages, and challenges.

Manual/hand application

Manual mask application is the most common method because it is simple, requires little setup, and no capital equipment investment. You simply squeeze the bottle to apply mask to the areas that need protection. Even though that sounds fool-proof, the way you hold the bottle can have a big impact on how easily the mask is removed.

It is common to hold the squeeze bottle straight up as you move the dispensing tip across the board. This can cause three potential problems:

1. Mask can stick to the inside of the vias and mushroom out on the other side. This creates a plug on the bottom side, and increases the chance of breakage when removing the mask.

2. If removing the mask in an aqueous cleaning system, the water will have trouble penetrating inside the masked holes.

3. When holding the bottle at 90°, the bead of mask tends to be thinner. This bead is your draw-string when peeling the mask off, so a thinner strip is more likely to break.

Pneumatic mask dispensing

Pneumatic dispensing systems reduce the variability in the application process, and open up the possibility of automatic dispensing. When using a pneumatic dispensing system, mask is pressurised with either compressed air or nitrogen and pushed through a dispensing tip. For this type of application method, clogged tips are the biggest headache.

Many masks have high shear-curing, which means pressure accelerates the curing process. If that is the case, the mask will tend to clog the dispensing tip as the pressure increases. WonderMASK P peelable mask, or WonderMASK WSOL and WonderMASK W washable masks have high shear curing, so will avoid this problem.

Cured bits of mask in the tank are also a concern, because they can be drawn through the dispensing system and clog the tip. Using nitrogen instead of ambient air to pressurise the system can avoid curing in the tank. If there is skinning in the tank or in the original mask container before the material is transferred, peel off the cured mask instead of mixing it into the uncured material.

If the viscosity of the mask needs to be thinned, carefully mix in deionised (DI) water. Mix slowly to avoid whipping, which adds air bubbles to the mask and can create voids.

Stencil printing mask

It is not uncommon for mask to be applied with a stencil, which is similar to SMT solder paste printing. Choosing an appropriate mask for stencil printing is critical, because viscosity has to be high enough to be printed without flowing under the stencil. Washable masks make stencil cleaning easier. Peelable masks either have to be cleaned before curing, or peeled after it fully cures. Avoid screen printing with a fine mesh screen because of potential cleaning problems.

How to apply temporary solder mask for conformal coating

Using mask for conformal coating is a simple process that requires little setup, and no capital equipment. First you apply the mask to the contact areas and allow the mask to fully cure. Then you apply the conformal coating over the masked area. After the coating is dry to the touch, but before it is fully cured, peel off the mask.

Peelable mask is recommended for conformal coating. Conformal coatings repel water, so a washable mask will be difficult to remove from under the coating. Natural latex is recommended, because synthetic mask can sometimes interact with harsh solvents used in conformal coating. For the cleanest masked edge, peel the mask before the coating is fully cured. Otherwise it could create a cracked, ragged edge, or even pull up the coating.

Curing temporary solder mask

Since fully curing mask can take anywhere from 30 minutes to a full day, the curing process requires planning to avoid bottlenecking the PCB assembly process.

While it might be tempting to push a masked board through the soldering process sooner rather than later, this tendency can cause serious problems. When uncured mask hits molten solder, the liquid components of the mask instantly vaporise and, if the cured skin is not thick enough, will forcefully exit. This can open voids in the mask and even cause the mask to pop and throw solder beads all over the PCB.

The pre-heat cycle in wave soldering equipment can speed up curing, but some pre-curing is still recommended. Before a masked board is put on the conveyor, the mask should be non-tacky with a thick skin. Beyond that, you will need to test within your own process because it depends on the mask material, the thickness of the bead, and the thermal profile. We do not recommend changing your equipment thermal profile to speed up the mask curing process. That can lead to other problems, like thermally stressing sensitive components.

If speed is the most important factor, consider natural latex solder masks. WonderMASK PX is the fastest curing mask available, so will fully cure within 20 minutes, depending on the thickness of the bead. Instead of skinning over, then curing on the inside like most masks, WonderMASK PX skins then thickens and cures throughout all at one time. That makes it perfect for when thick beads of mask are required.

How to remove temporary solder mask

Since we are talking about temporary solder mask, it needs to be removed at the end of the PCB assembly process. Peelable masks are commonly removed by hand or with tweezers. Techspray offers several peelable masks:

• WonderMASK P is a synthetic latex mask, so does not contain ammonia. This makes it easier on the nose, and safer on sensitive metals like gold, brass or aluminum.

• WonderMASK PX is our fastest curing mask, and ideal when you are applying thick beads.

• Techform TC-533 was previously available from Kester. It cures quickly and has high tinsel strength. It is ideal if breakage is a concern, or for conformal coating.

Washable mask is designed to be removed in aqueous inline or batch wash systems. If you are using a closed-loop system, which filters and recirculates wash water, make sure you use a mask that is compatible with your physical filters and ion beds. Techspray offers three different washable masks:

• WonderMASK WSOL is fully soluble in water, so is compatible in closed-loop wash systems. It will not damage ion filter beds or clog mesh filters.

• WonderMASK W is non-flammable and cures more quickly than WonderMASK WSOL.

• WonderMASK WA is similar to WonderMASK W, but with a viscosity that is better suited for pneumatic dispensing systems.

If you are removing mask in an inline or batch aqueous system and are experiencing foaming, it is an indication that either a) too much mask material is being passed back into your cleaning system or b) it is interacting with dissolved flux in the same wash water. This is generally solved by replacing your wash water with fresh DI water. Techspray Defoamer DF1 can be added as a stopgap solution.

| Tel: | +27 11 704 3020 |

| Email: | [email protected] |

| www: | www.testerion.co.za |

| Articles: | More information and articles about Testerion |

© Technews Publishing (Pty) Ltd | All Rights Reserved