Temporary solder mask is a type of material used in electronics manufacturing to protect specific areas of a printed circuit board during the soldering process. It can be easily peeled or washed off after soldering is complete. While it is most used to mask open vias in a wave soldering process, operators find all kinds of creative ways to use solder mask to solve process challenges.

Wave soldering

In wave soldering, where an entire PCB is passed over a wave of molten solder, temporary solder mask can be applied to protect areas that should not be soldered, such as gold-plated contacts, through-hole components, or connectors that require a different soldering method.

Selective soldering

In selective soldering, specific areas of a PCB are soldered using a focused jet of solder. Temporary solder mask can be used to define the regions where solder is applied, allowing precise control over the soldering process.

Component protection

Temporary solder mask is applied to protect sensitive electronic components, such as connectors, switches, and delicate

surface-mounted devices (SMDs), from accidental soldering or flux splatter during the assembly process.

Rework and repair

When reworking or repairing a PCB, temporary solder mask can be used to cover nearby components that need to be protected from heat or soldering iron contact. It ensures that only the intended area is exposed to the rework process.

Conformal coating

Temporary solder mask can serve as a temporary barrier during the conformal coating process, which involves applying a protective coating to the PCB. It prevents the conformal coating from adhering to specific areas, such as connectors or test points, that need to remain accessible.

Adhesive for reflow of two-sided PCBs

Temporary solder mask can be used as a removable method of affixing components during PCB assembly, instead of more permanent adhesives. It provides a temporary adhesive-like property and prevents components from falling off during the reflow process, especially when a double-sided board is flipped over for a second pass.

Painting and powder coating

While temporary solder mask isn’t commonly used for painting and powder coating processes, it can offer flexibility not offered by masking tapes, silicone plugs, or custom-moulded silicone caps. Natural latex peelable masks, like WonderMASK PX and Techform TC-533, are recommended because their tensile strength can avoid breakage when removing.

Anodising and plating

Using a temporary solder mask for anodising and plating processes can be a useful technique to protect specific areas of a metal surface from being coated or plated. The solder mask acts as a barrier, preventing the anodising or plating solutions from reaching the masked areas.

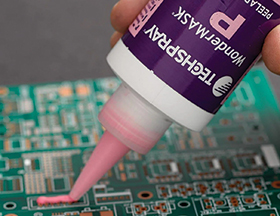

Techspray WonderMASK temporary solder masks offer several advantages for electronics assembly and PCB manufacturing processes. It is non-ammoniated, non-flammable, and easily peelable. The spray has a cure indicator, darkening as it cures, and it is compatible with gold and copper leads.

| Tel: | +27 11 704 3020 |

| Email: | [email protected] |

| www: | www.ama-sa.co.za |

| Articles: | More information and articles about Allan McKinnon & Associates |

© Technews Publishing (Pty) Ltd | All Rights Reserved