Actel designed its Fusion chip, the world's first mixed-signal FPGA, with power sequencing and management applications in mind.

All the benefits of a single-chip, Flash-based FPGA are available in Fusion devices, plus configurable analog, embedded Flash memory, and numerous power management control features.

With Fusion, system development is completely integrated using the SmartGen IP core generator, delivered within the Libero IDE (integrated design environment). SmartGen provides a simple, graphical way to configure the analog and Flash memory systems. The user also has the flexibility of replacing or augmenting SmartGen IP with user logic or a microprocessor for explicit control of the analog system and for software-customised system applications.

Fusion supports the following power control functions:

* Power sequencing: controls ramp-rate and timing; customises voltage thresholds; reconfigures power sequence; provides a clean power-up profile.

* Power management: monitors analog voltage, current, and temperature; flags voltage, current, and temperature thresholds; provides system protection based on threshold flags; controls power ramp-up and shutdown.

* Power-on/brownout reset: detects power-on and brownout conditions; resets user logic or an external system.

Since power management applications often require low power consumption, the Fusion internal voltage regulator allows them to operate off a single 3,3 V supply. Fusion supports very low power standby or sleep modes with automatic wake-up at regular intervals or when external stimulus is applied.

Fusion makes an excellent system master solution because it operates from a single 3,3 V supply and it is a level 0 live at power-up (LAPU) device. Fusion can monitor, sequence, and manage several additional power supplies.

Application details

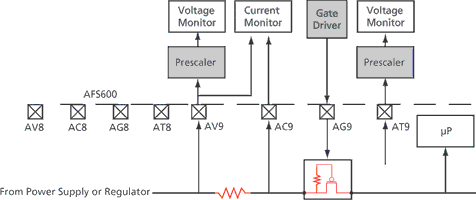

Fusion analog I/Os are arranged in an analog quad (AQ) configuration (three inputs matched with a MOSFET gate driver). Fusion devices support between five and 10 AQs. Each quad can easily monitor supply side or load side voltage, current, and temperature. The gate driver output provides adjustable control of external power MOSFET with either ramp-rate control or voltage potential control. These can be used for power sequencing and voltage and current protection of the load. Figure 1 shows the details of a power management system implemented in a Fusion device (pin AT9 is used as a voltage monitor channel in this example).

Power-up sequencing

Fusion can be configured as a power system supervisory device with continuous monitoring of all power supplies. When power supplies reach user-defined threshold values, Fusion can turn on the pass MOSFET transistors to provide power to the load. Power-up sequencing is provided either by ramp-rate control or by voltage monitoring.

To use ramp-rate control, the user must set the driving strength of each MOSFET gate driver. The ramp-rate is defined based on the different loads and their voltage threshold, which provide a clean ramp-up profile. Using voltage monitoring, the user must define the turn-on condition for one power supply based on the power-up status of another power supply. For example, the user would turn on a 1,5 V power supply only when the 3,3 V power supply exceeds 3,275 V. Timing and logic for power-up sequencing is implemented by the user inside the FPGA fabric, and it is therefore completely configurable and controllable by the user.

Power management

After the power MOSFETs are on, Fusion monitors voltage on both the supply and the load side. It monitors the current flowing to the load to ensure acceptable system conditions. Fusion compares the voltage and current values to use pre-set thresholds and sends out alerts when applicable. It also turns off corresponding MOSFETs to protect the load when the voltage and/or current is outside of the defined limits. Fusion can then turn the MOSFETs back on when the value comes back into normal range. Statistics of each power supply, such as voltage values, current values, over limit alerts, and turn-on/off times can all be recorded in Fusion using the embedded Flash memory.

Power-down sequencing

Not only can Fusion sequence the power-up of the system, it can also turn off the power supplies when triggered by user logic, such as through the use of internal timers or by any other internal or external events. Before turning off all power supplies, Fusion can also record the status of each device under monitoring for later analysis.

Power-on/brownout reset

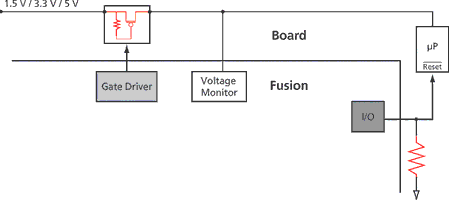

Fusion can generate reset to other devices on a system or respond to brownout conditions. In the example shown in Figure 2, as the system board is powered up, Fusion sends a reset signal to the microprocessor through standard FPGA I/Os as it applies power to the microprocessor. Fusion can also assert a reset signal whenever a power supply (VCC) drops below a programmable threshold voltage, and then keep the reset asserted for a specified period of time after VCC has risen above the threshold.

Conclusion

Actel Fusion has all of the features needed to implement a power sequencing and management system. It monitors voltage, current, and temperature, and it has MOSFET gate drivers. The embedded Flash memory and Flash-based FPGA fabric enable a simple single-chip solution. The SmartGen user interface and IP allow customers to implement their applications simply and quickly. With all of these features tied to Flash FPGA logic, the power management system can be completely customised by the user, offering flexibility unmatched by any other power management control solution.

| Tel: | +27 11 315 8316 |

| Email: | [email protected] |

| www: | www.asic.co.za |

| Articles: | More information and articles about ASIC Design Services |

© Technews Publishing (Pty) Ltd | All Rights Reserved