The world is full of connectors, most of which will never be seen. They are in phones and computers, washing machines and cars. Not only are there lots of connectors in the world, but they are available in a bewildering variety of designs. This is confusing for the designer and a headache for anyone tasked with buying the right part number. Why can’t there be one connector that does it all?

In large part, this variety has been caused by the way that connectors have evolved with the electronics industry they serve. In one example, as electrical systems in cars became more sophisticated, so too did the connectors that were designed for them. In another example, the birth of microelectronics led to connectors with a larger number of pins to deliver signals. As can be seen, connectors are often designed specifically for the roles that they fulfil.

The result is that no one connector can perform all tasks perfectly. One only needs to look at the D-sub connector that has been used in the industry for over 60 years. Originally designed for the aerospace industry, it has become one of the most familiar connectors in the world. The family includes mixed D-sub connectors that are fitted with both power and signal contacts within the same shell. Despite their multi-role design, they are limited in the roles they can play.

This limitation exists because the capabilities of electrical contacts within a connector are only partly determined by their design. Their arrangement within the connector, and their relationship with other contacts, is just as important as their form. In the example of the mixed D-sub connector, the large power contacts are great for carrying high currents, but the spacing between them prevents them from being used for high voltages.

Even the arrangement of the small signal contacts will limit their capabilities. The D-sub was designed at a time when signal speeds were a tiny fraction of today’s standards. The demands of modern high-frequency, high-bandwidth communications make D-subs unsuitable for this role. The linear design of the connector limits its versatility in these newer applications.

Enter the open pin-field

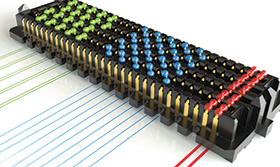

An alternative to traditional, linear connectors can be found in the open pin field grid array. The concept behind a pin field array is that it provides many contacts that are not limited to a single role. The connector itself is designed so that each contact can perform any one of several roles. To understand how it provides this level of versatility, let’s look at some of the design features that make these connectors special.

The first difference is in the contact design itself. Many traditional linear connectors use conventional pin-and-socket contact designs. For a connector with large numbers of contacts, these have a few drawbacks. The first is the size of the contact – in a pin and socket arrangement, the socket must be larger than the pin for the system to work, which limits the density that a connector that uses them can achieve.

The second drawback is the mating force required to insert and withdraw them. While the force required to insert a single pin may be low, when multiplied by several hundred (the SEARAY is available with more than 500 contacts) the effort required to mate the connector is significant.

Samtec’s open pin field connectors use the Edge Rate contact, which has been designed specifically for high-speed applications, especially where they need to be cycled frequently. The surface of the contact is milled to create a smooth mating area. This reduces the force required to mate it and increases the expected life of the connector. The Edge Rate is also smaller than conventional pin-and-socket designs, keeping the connector compact even while offering very high pin counts.

The design of the connector itself also plays an important role in delivering flexibility. The contacts are housed in the connector body in such a way as to minimise electrical interference caused by broadside coupling and crosstalk. Along with the design of the contacts, the connector can therefore be used for high-speed applications.

The grid layout of the contacts allows designers to choose the function of each contact to optimise its performance: differential pairs for a high-performance application, a layout that maintains signal integrity, or single-ended signals? It can accomplish them all.

A pin grid array can even be used for power applications. Each individual contact can carry more than 5 A although, allowing for temperature, 1,5 A might be a more realistic figure. However, a connector with 500 contacts, each carrying 1,5 Amps, can deliver a lot of power.

Is this the ultimate, do-everything connector? While it may not be suitable in all situations, for any engineer that needs this level of flexibility in board-to-board or board-to-cable applications, it has a lot to offer.

For more information contact Spectrum Concepts,

© Technews Publishing (Pty) Ltd | All Rights Reserved