Within smart sensors, wireless and portable devices are expected to be the primary growth drivers. Monitoring industrial machines using wireless environmental sensors (temperature, vibration) has one clear goal: to detect when the equipment being monitored deviates from healthy operation.

For industrial wireless sensor applications, low power consumption, reliability, and security are consistently ranked as the most important requirements. Other requirements include low total cost of ownership (minimal gateways, maintenance), short-range communication, and a protocol capable of mesh formation for factory environments that include lots of metallic obstacles (meshing networks help to mitigate possible signal path shielding and reflections).

Industrial applications and wireless standards requirements

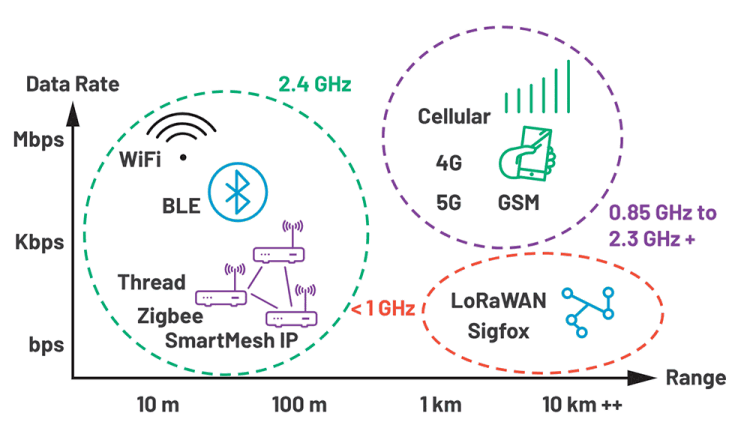

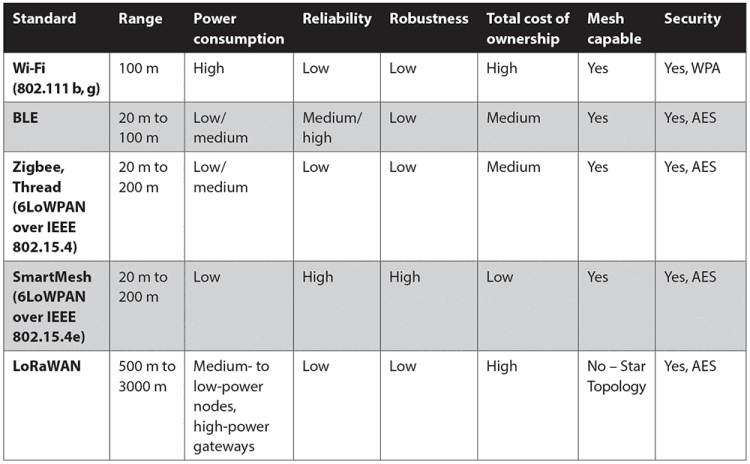

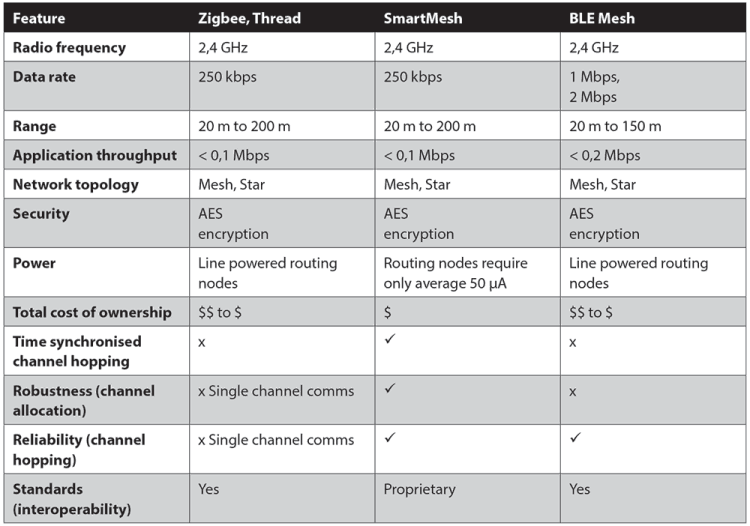

Figure 1 provides an overview of wireless standards, and Table 1 ranks selected wireless standards against key industrial requirements. It’s clear that BLE and SmartMesh (6LoWPAN over IEEE 802.15.4e) offer the best combination of low power consumption, reliability, and security for industrial applications. Thread and Zigbee offer low power and secure mesh implementations but score lower on reliability.

Table 2 provides more details for the Zigbee/Thread, SmartMesh, and BLE mesh standards. SmartMesh includes a time synchronised channel hopping (TSCH) protocol, where all nodes in a network are synchronised and communication is orchestrated by a schedule. Time synchronisation results in low power and channel hopping results in high reliability. The BLE standard also includes channel hopping, but has some constraints in comparison to SmartMesh, including line powered routing nodes (increasing system cost and power), and TSCH is not supported. As previously mentioned, Zigbee/Thread score low on reliability and do not offer many advantages compared to BLE.

Based on the information above, this article will focus on SmartMesh and BLE mesh as the most suitable wireless standards for industrial condition monitoring sensors.

Analogue devices wireless condition monitoring sensors

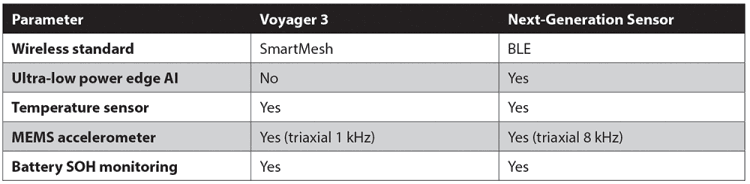

Table 3 provides an overview of Analog Devices’ Voyager 3 Wireless Vibration Monitoring Platform and next-generation wireless condition monitoring sensors. Voyager 3 uses a SmartMesh module (LTP5901-IPC). An AI-enabled vibration sensor (still in development) uses a BLE microcontroller (MAX32666). Both sensors include temperature and battery state of health (SOH) sensors. The Voyager 3 and AI version sensors use ADI MEMS accelerometers (ADXL356, ADXL359) to measure vibration amplitude and frequency for industrial equipment. Increasing vibration amplitudes and frequencies are identified using FFT spectra, which can indicate faults such as motor imbalance, misalignment, and damaged bearings.

Figure 2 provides an overview of a typical operation for Voyager 3 and the AI-enabled vibration sensors. Like many industrial sensors, the duty cycle is 1%; most of the time the sensor is in a low power mode. The sensor wakes up periodically for bulk data gathering (or in a high vibration amplitude shock event) or to send the user a status update. The user is typically notified with a flag to state that the monitored machine is in good health, and the user is given the opportunity to gather more data.

Artificial intelligence at the edge

The next-generation wireless sensor includes the MAX78000 microcontroller with AI hardware accelerator. This AI hardware accelerator minimises data movement and leverages parallelism for optimal energy use and throughput.

Wireless industrial sensors currently available on the market typically operate on very low duty cycles. The user sets the sensor sleep duration, after which the sensor wakes up and measures temperature and vibration, and then sends the data over the radio back to the user’s data aggregator. Commercially available sensors typically quote a five-year battery life, based on one data capture every 24 hours, or one data capture every four hours. The next-generation sensor will operate in a similar fashion, but take advantage of Edge AI anomaly detection to limit the use of the radio. When the sensor wakes up and measures data, the data is only sent back to the user if a vibration anomaly is detected. In this way the battery life can be increased by at least 20%.

For AI model training, the sensor collects healthy data for the machine, which is then sent over the air to the user for AI model development. Using the MAX78000 tools, the AI model is synthesised into C code, and then sent back to the wireless sensor and placed in memory. When the code is deployed, the wireless sensor wakes up at predefined intervals. Data is gathered and an FFT is generated. From the FFT, the MAX78000 makes an inference based on this data. If no anomaly is detected the sensor goes back to sleep. If an anomaly is detected the user is notified. The user can then request FFT or raw time domain data for the measured anomaly, which can be used for fault classification.

This article has introduced smart wireless industrial sensor design. To continue reading the sections on device security, low power consumption, and reliability and robustness, visit www.dataweek.co.za/*swisd

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved