Lightning, inductive load switching or capacitor bank switching may cause transient over-voltage conditions in AC line voltage applications such as white goods and appliances. Metal oxide varistors (MOVs) are typically used for transient over-voltage suppression in AC line voltage applications. However, in these applications there also exists the potential for a sustained abnormal over-voltage/limited current condition that may cause the MOV to go into thermal runaway, resulting in overheating or outgassing.

This article describes new thermally enhanced MOVs that help protect a wide variety of low-power systems against damage caused by over-current, over-temperature and over-voltage faults, including lightning strikes, electrostatic discharge (ESD) surges, loss of neutral, incorrect input voltage and power induction.

Helping to reduce component count

Under normal operating conditions, the AC line voltage applied to an MOV is not expected to exceed the device’s maximum AC root mean voltage (VACRMS) rating. Provided that the transient energy does not exceed the MOV’s maximum rating, short-duration transient events are clamped to a suitable voltage level. However, a sustained abnormal over-voltage/limited current condition, such as a loss of neutral, may cause the MOV to go into thermal runaway.

Protecting the MOV from thermal over-dissipation is frequently accomplished with a thermal cut-off (TCO) device, placed in series with the MOV. A typical line voltage transient protection scheme may also incorporate a thermal protection element, such as a fuse, to protect the system from damage caused by an over-current condition that exceeds a predetermined level.

Helping to prevent over-current conditions and thermal runaway

TE Connectivity’s integrated 2Pro device is designed to help manufacturers meet industry test requirements, reduce component count and improve equipment reliability. The device combines a polymeric positive temperature coefficient (PPTC) over-current component with an MOV component, resulting in one thermally protected device to help provide resettable current limiting for over-current conditions and voltage clamping during over-voltage events.

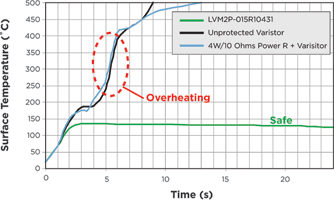

Standard unprotected MOVs are typically rated to 275 VACRMS for a universal input voltage range. In a loss of neutral condition, they may overheat with negative consequences, even if a fuse or power resistor is used upstream. In a worst case scenario, as shown in Figure 1, a voltage of 400 V a.c. instead of 230 V a.c., derived from a loss of neutral, is applied. In such a limited current condition, the unprotected MOV will first fall to low impedance of a few Ohms. However, due to the high amount of energy present, it is likely to rupture. If there are devices placed on the AC line return path to limit current flow, these may also overheat due to the failure of the MOV.

Figure 1 illustrates the effects of these abnormal over-voltage conditions on three devices or a combination of devices:

1) Raychem LVM2P-015R10431.

2) Single MOV (10 mm, 275 VRMS).

3) MOV/4W Power Resistor (10 Ω).

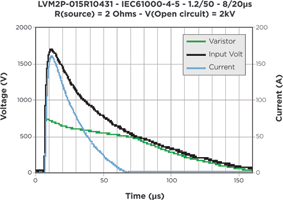

The 2Pro device’s PPTC element helps prevent thermal runaway, maintaining varistor surface temperature at less than 150°C. It also prevents the device from reaching unsafe temperatures caused by over-voltage transients. This approach helps manufacturers comply with IEC 60950 and IEC 60335 and helps equipment remain operational after specified lightning tests according to IEC 61000-4-5 (Figure 2). Also, because the PPTC element is in series with the MOV, no additional over-current protection is required.

How it works

Although the AC line voltage applied to an MOV is not generally expected to exceed the device’s maximum continuous operating voltage rating, over-voltage transients may occur that exceed these limits. By integrating PPTC technology with the MOV, the 2Pro device improves over-current and thermal protection under conditions where the MOV is exposed to prolonged continuous over-voltage events. In the event of an over-voltage transient, such as a loss of neutral event shown in Figure 3, the PPTC element in the 2Pro device heats up, trips and goes into a high resistance state, helping to reduce the risk of MOV device failure.

The LVM2P-015R10431 parts used in the test scenarios described in this article are 10 mm radial-leaded devices that utilise three leads. In the circuit diagram, shown in Figure 4, the first lead is connected to the PPTC element, the second lead is connected to the MOV/PPTC series connection (providing a path to ground) and the third lead is connected to the MOV.

The single, small form factor circuit protection device helps reduce component count and footprint size, and helps provide a safe failure mode in case of varistor overstress. It also helps equipment comply with IEC 60950/IEC 60335 and IEC 61000-4-5 testing requirements.

Bottom line

Coordinated circuit protection helps reduce board space requirements and component count, and improves equipment reliability. The resettable functionality of the 2Pro device can also help manufacturers reduce warranty returns and customer complaints related to transient over-current and over-voltage incidents.

In addition to white goods and appliances, 2Pro devices help provide protection in a wide range of AC line applications, including AC LED lighting systems, PLC network adapters, cellphone chargers, AC/DC power supplies, (up to 30 VA as input power for 230 V a.c. input voltage), modem power supplies, AC panel protection modules and AC power meters.

For more information contact Jeva Narian, Arrow Altech Distribution, +27 (0)11 923 9600, [email protected], www.arrow.altech.co.za

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved