Thanks to technology, a quiet revolution is taking place inside the innocuous looking electricity meter.

Figure 1 shows an example of a traditional electromechanical meter – first developed in the late 19th century – that has a spinning disc and a mechanical counter display. This type of meter operates by counting the revolutions of a metal disc that rotates at a speed proportional to the power drawn through the main fuse box. Nearby coils spin the disc by inducing eddy currents and a force proportional to the instantaneous current and voltage. A permanent magnet exerts a damping force on the disc, stopping its spin after power has been removed.

The first step in meter evolution was the replacement of electromechanical meters with solid-state electronic meters.

Electronic meters measure energy using highly integrated components, such as Analog Devices’ various families of energy measurement ICs. These devices digitise the instantaneous voltage and current via a high-resolution sigma-delta ADC. Computing the product of the voltage and current gives the instantaneous power in watts. Integration over time gives energy used, which is usually measured in kilowatt hours (kWh). The energy data is displayed on a liquid-crystal display (LCD), as shown in Figure 2.

Electronic meters offer several benefits. In addition to measuring instantaneous power, they can measure other parameters such as power factor and reactive power. Data can be measured and stored at specific intervals, allowing the utility to offer price plans based on time-of-day usage. This allows savvy consumers to save money by running major appliances, such as washers and dryers, during lower-cost, off-peak periods; and utility companies can avoid building new power plants because less capacity is required during peak periods. Electronic meters are not influenced by external magnets or orientation of the meter itself, so they are more tamper-proof than electromechanical meters. Electronic meters are also highly reliable.

Analog Devices has been a key player in the transition from electromechanical meters to electronic ones, shipping more than 225 million energy measurement ICs to date. According to IMS Research, 75% of all energy meters shipped in 2007 were electronic rather than electromechanical.

Electronic meter opens up new possibilities

Once meter data is available in electronic form, it becomes feasible to add communications to the meter, allowing it to use automatic meter reading (AMR) to access data remotely via the communication link. Meter manufacturers have developed different system architectures for remote reading, broadly classified as walk-by, drive-by, or networked systems. A drive-by system is shown in Figure 3.

In this case, the utility company sends out a van with an onboard wireless data collector. The van drives through the neighbourhood efficiently collecting meter data. A drive-by system improves the number of meters a utility employee can read in a day fivefold compared to walk-by systems and over tenfold compared to manual meter reading. In a networked system, meter data is fed to a fixed data collector, which is typically located on a pole at the end of the street or neighbourhood. The data is then fed back to the utility via a broadband or cellular backbone.

AMR to AMI

Initially, replacing manual reading with AMR systems was seen simply as a way to reduce labour costs, but this is changing as the industry recognises that AMR allows utility companies to conveniently provide higher order benefits and services, such as realtime pricing to promote better energy efficiency, instant reporting of fault detection, and more accurate data for profiling usage within the network.

AMR is sometimes replaced with advanced metering infrastructure (AMI) to highlight the evolution from simple remote meter reading. AMI networked metering systems can be implemented using technologies ranging from satellites to low-cost radios. The two dominant emerging technologies are RF – using the unlicensed industrial, scientific and medical (ISM) band – and powerline communications (PLC).

RF technology uses low-power, low-cost radios to wirelessly transmit the meter information, whereas PLC uses the powerline itself. Each of these technologies has its pros and cons. For water and gas meters in particular, RF technology is becoming the dominant choice due to the safety concerns of having power mains near water or gas. Water meters also have the added complication of often being buried underground.

With electricity meters, a combination of both approaches is looking most likely, with North America favouring RF and Europe favouring powerline. In the US, several houses are typically tied to a single transformer, making PLC less economical. In some implementations, utility companies are deploying AMI using a blend, with powerline used to communicate from the data collector to the electricity meter and RF used between the electricity meter and other in-home meters or devices.

Designing the RF section of an AMR/AMI-enabled utility meter

Utility meters are often located in or around homes that have an ever-increasing number of wireless devices, so ensuring reliable radio communication is a challenge. High performance from the RF circuitry is required to reject large unwanted signals from devices such as a wireless LAN, while decoding the wanted signal that might be as low as fractions of a microvolt at the input to the radio.

Good radio sensitivity is also required because this translates into longer signal transmission ranges. Remember that the meter can be located in a basement or, even worse, underground, yet it needs to communicate with a radio on a pole some blocks away or with a utility van on the street. The lower the sensitivity, the closer the receiving radio needs to be to decode the messages correctly. For a mobile drive-by system, this simply means the van must drive closer to the house, but fixed network infrastructure must use smaller cells and a corresponding larger number of data collectors. High sensitivity will thus minimise network infrastructure costs.

Low power consumption is critical in battery-powered gas and water meters. Meter vendors often try to reduce power consumption in an energy meter because this allows them to port the same design to a water or gas meter. Also, in order to operate in the unlicensed portion of the spectrum, the communication protocol used by the meter and reader must comply with the radio emissions regulations in the country of operation. Several unlicensed bands exist worldwide, the most common ones being at 900 MHz, 2,4 GHz, and 5,8 GHz.

A majority of meter manufacturers have chosen radios in the 900 MHz bands for the links between meters, and between meter and data collector. Radios at these frequencies offer better communication range for a given power budget than competing 2,4 GHz technologies and thus allow much wider cell coverage for a given base station or data collector.

From the utility’s perspective, however, a drawback of using this frequency band has been the lack of available standards. The sub-GHz bands are clearly the best technology choice for battery-powered gas and water meters, inspiring increasing demand for standardisation to allow interoperability between different manufacturers’ systems. Wireless M-Bus, which has grown out of the wired M-Bus users group, is one example of a standard for communication between meters, and between meter and data collector. M-Bus is now part of the EN European Normative standard detailed in EN 13757. The Wireless M-Bus protocol is detailed in the EN 13757-4 variant. Other standardisation efforts at 900 MHz are also under way.

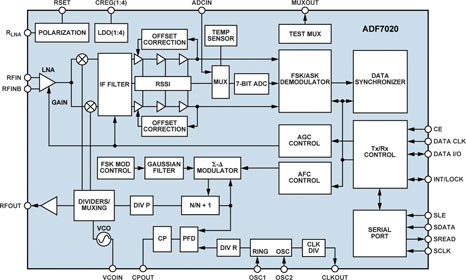

The ADF7020 and the soon-to-be-released ADF7023 transceivers are examples of 900 MHz radios that are designed with metering in mind. Both devices are also suitable for systems that must comply with the Wireless M-Bus standard. A block diagram of the ADF7020 is shown in Figure 4.

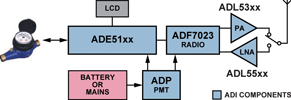

The ADF7020 operates in the licence-free ISM bands at 433 MHz in China, 868 MHz in Europe, and 915 MHz in North America. It integrates the full transmit and receive RF sections as well as analog and digital basebands. Implementing a radio card for an AMR-enabled utility meter typically requires the ADF7020, an antenna, a small number of external passives, and a simple microcontroller to run the communication protocol, as shown in Figure 5. The ADF7020 eases the load on the external microcontroller by integrating a low-power, 8-bit RISC core to run some of the lower-level communication functions. This can eliminate the need for a separate communications-specific microcontroller in many cases.

HAN network

With a communications-enabled meter to be available in many homes in the future, utility companies and energy regulators are looking to the future to see how they can leverage the technology to improve energy conservation and awareness. Using this concept, sometimes called the smart grid, utility companies can use networks that will extend all the way into customers’ homes to actively manage the transmission load. One such service could provide realtime price information, allowing the consumer to modulate energy usage.

At times of peak load, during a heat wave for example, the utility company could send a message to the house, telling home owners that prices would be going up for the next hour and encouraging them to switch off appliances. This would require an in-home display where such a message could be shown. Going one step further, the utility company could communicate to the devices in your home via the meter, turning up the thermostat or turning off a pool pump, for example.

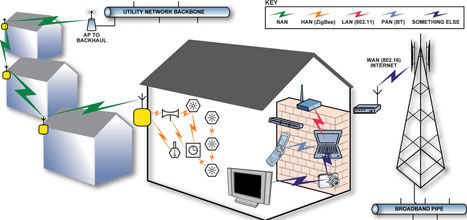

This system would require communication between the meter and the home appliances and is sometimes termed the home area network (HAN). 900 MHz radios such as the ADF702x and ZigBee radios are both finding favour here.

Most industry participants recognise that a fully working home area network linked with the advanced meter infrastructure is a number of years away, yet the benefits of such a system mean that many companies are actively involved in developing solutions for home area networks today. A graphical depiction of the home area network is given in Figure 6.

Conclusion

AMI and the smart grid are seen as key potential technologies to improve energy efficiency, ultimately helping in the goal to reduce carbon emissions. With its range of RF transceivers, energy measurement chipsets, RF amplifiers, isolation products and powerline controllers, Analog Devices is positioning itself to be a major player in energy efficient solutions.

© Technews Publishing (Pty) Ltd | All Rights Reserved