The XC800 family from Infineon includes what are said to be the industry’s first 8-bit microcontrollers with powerful field-oriented control (FOC) for complex and efficient motor control applications. This advanced motor control can improve consumer and industrial drives by providing higher efficiency and better dynamic response, and reducing audible noise.

Application kits and powerful tools support the fast and easy implementation of the new motor control techniques. With just a few mouse clicks, the DAvE (digital application virtual engineer) drive application code generator will create customised code reflecting choice of motor, speed and various control options for highly efficient motor control designs.

According to a study by the Energy Information Administration (EIA) in 2007, a third of the world’s energy consumption is accounted for by electric energy, which amounted to about 16,4 million gigawatt hours in 2004. This figure is predicted to double by 2030.

One major way to reduce energy is to use electronics in inverters, which could save 30 to 40% of the electricity required for motor-control applications. By adopting variable-speed drives using advanced control techniques such as FOC, worldwide consumption of electricity could be lowered by over 20%.

Advanced control schemes such as FOC allow manufacturers to reduce the size of the motors required for given tasks, yielding higher efficiency, better dynamic response and lower torque ripple. Using FOC in combination with cost-effective 8-bit microcontrollers can help motor-control developers meet stringent energy regulations while saving money. The DAvE Drive automation code generator can reduce time-to-market and pave the way to sophisticated and power-efficient motor control designs.

FOC for improved motor efficiency

The 8-bit microcontrollers in the XC800 family offer scalable solutions for different types of motor-control methods including block commutation, FOC and both FOC and PFC (power factor control) for complex motor drives. FOC results in smooth and energy-efficient operation at all speeds, and is increasingly being adopted for consumer and industrial motor control.

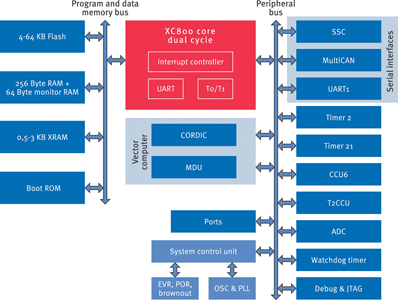

Achieving this efficient method of control with a low-cost but highly optimised 8-bit microcontroller redefines the economic models for developers of appliances and other motor-controlled products such as fans, pumps and compressors. FOC is currently implemented on the 8-bit XC886, XC888 and XC878 microcontrollers by combining an 8051 core and a so-called ‘vector computer’, which performs 16-bit arithmetic operations.

This vector computer has two parallel operating units: the MDU, a 16-bit multiply-and-divide unit, and the CORDIC, a 16-bit coprocessor dedicated to vector rotation and angular calculations. Unlike most competitive FOC implementations that are hard-coded, the solutions based on XC800 8-bit microcontrollers offer the added benefit of software reprogrammability to give developers more versatile application options.

By using FOC, the efficiency of an electrical motor can be increased by up to 95%, providing less power consumption, less noise and excellent torque dynamics. The implementation and execution of FOC requires an optimised microcontroller architecture and easy-to-use tools to reduce time-to-market. The architecture of the XC800 family is shown in Figure 1.

Application-focused development support

Application-focused systems are very helpful when an engineer needs to expand a company’s design capabilities. For example, a company that produces electronic controls for brushed DC motors may need to move quickly to more efficient brushless DC (BLDC) motors for some newer product lines. The best solution for rapid development and demonstration would be to find a system that is easy-to-use, self-contained, includes an IDE and application software, and provides fairly extensive documentation. With all these elements, including the BLDC motor, the design team can demonstrate the working technology. The solution is general and still needs to be adapted to the target products, but the basic feature set is in place.

Two major topics influence the ease-of-use of today’s microcontrollers for software developers: the quality of the software tool chain and the availability of reference designs. Microcontroller families are supported by the full suite of development tools, including evaluation boards, debuggers, compilers and documentation. Configuration tools such as DAvE help developers to program microcontrollers by offering intelligent wizards.

DAvE makes it possible to configure the chip to work correctly as designed, and automatically generate C-code with appropriate driver functions for all of the on-chip peripherals and interrupt controls – interacting directly with compiler IDEs. Pre-installed ready-to-run examples, step-by-step guidelines and further advanced tools such as automatically generated start-up code can help a designer get started quickly.

An auto-code generator, for example, is another important key to a quick transition from purchasing the microcontroller to turning the motor. In this respect, DAvE Drive version 2 shortens the evaluation time for motor control developers because the motor control code can be generated via a GUI instead of handwriting thousands lines of code. DAvE Drive gives hardware engineers access to know-how in control techniques for electronic systems, and it uses the full power of the related microcontroller, eg, it generates optimised FOC code for XC886 using its vector computer. Without this system, a developer would usually require expert knowledge in both motor control and assembler programming.

The next level of support is to provide an entire reference system comprising microcontrollers, sensors and power devices. This is an excellent platform for training, evaluation and starting development, as the kit can be directly connected to an application such as a 3-phase motor.

DAvE Drive application code generator

DAvE Drive is an application-centric add-on to DAvE, which provides initialisation, configuration and driver code to ease programming. This tool generates complete algorithms in source code (C and Assembler), ready to be compiled and debugged by popular tools such as the Keil or Tasking compiler.

DAvE Drive supports both BLDC and PMSM motor types and different control algorithms such as block commutation with Hall sensors and sensorless FOC. Motor types already in the motor type library can be used, or the user can add custom characteristics of the chosen motor to the library, such as nominal voltage, phase inductance and resistance. Various control schemes (open loop, speed control, current control or speed inner current control) are supported. The tool generates optimised motor control algorithms, utilising the features of the microcontroller’s vector computer.

A scalable low voltage PMSM motor drive kit is supported by the new DAvE Drive version 2. The complete DAvE Drive application kit provides a scalable MCU solution with a drive card featuring the XC886 8-bit MCU with vector computer, power board rated up to 400 W (22–56 V d.c., 7,5 A) and the DriveMonitor USB-CAN bridge for realtime monitoring. A free tool chain including SDCC compiler and an IDE are available to let users start development without limitations.

DAvE Drive is available as a free download at www.infineon.com/davedrive.

For more information contact Davis Moodley, Infineon, +27 (0)11 706 6099, [email protected]

© Technews Publishing (Pty) Ltd | All Rights Reserved