The number of devices now being produced in SMT format has risen substantially.

On the transformers' mains side however, some elements are still to be found that have not changed to the new SMT mounting format yet. At least with regard to overload and short-circuit protection, SIBA has developed and now made available, new SMT fuse-links for power supply protection.

Miniature fuses

Most common are 250 V electronic fuse-link devices with dimensions of 5 x 20 mm as standardised to IEC 60 127 part 2. After more than 50 years of production this basic design has not changed (Figure 1). The fuse-links are available with various characteristics enabling optimal device protection. In combination with a fuse-holder, fuse-links can be easily changed when blown. Fuse-holders are often easily accessible, so choice of a suitable fuse-link after a fault current is up to the user - trusting that the same characteristic and rated current will be chosen.

About 20 years ago, the problem of changing fuses was eliminated by the introduction of sub-miniature fuse-links (Figure 2) that, with radial leads fastened directly to the PCB through mounting holes, it would be possible for authorised persons to change them. A further advantage is the reduced space required on the PCB in comparison to the cylindrical fuse-link. With a diameter of about 8,5 mm, two SMD fuse-links could be placed within the same area.

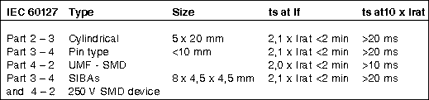

For mains inlet application, 'slow blow' fuse-links are predominant. To resist potentially high inrush currents, the fuse-links interrupt a fault equal to 10 times rated current at a time longer than 20 milliseconds. Slow-blowing fuses are very durable. If loaded with 2,1 times rated current, they interrupt the fault current in a time less than two minutes.

Depending upon location and mains proximity, fuse-links with 'low' (35 A and/or 10 X Irat), 'enhanced' (150 A) or 'high' (1500 A) breaking capacity can be selected. Because of the lower short-circuit currents that can be expected at applications on PCBs, only fuse-links with small breaking capacities are mostly required.

The third generation

The change to the surface mount method was a special challenge for fuse manufacturers, especially with respect to further miniaturisation. Meanwhile straight fuse-links with dimensions down to 0,8 x 1,6 mm can be found in IT industrial devices. These usually superfast fuse-links manufactured in modern chip technology are used due to the very short contact distance, but only for low voltages.

As required by IEC 60127 part 4, clearly larger contact distances are necessary for use at voltages above 125 V, which inevitably lead to larger fuse dimensions. Beyond that, a sufficient length of the fuse element inside the fuse-link is needed to interrupt these high voltages.

In addition, there are special demands of the users. Within the range of voltage supply, higher demands are often given through climatic stress and cyclic loads as well as requirements for shock and a vibration stability of the devices.

SIBA's SMD fuse-links for 250 V

SIBA introduced a new SMD fuse-link measuring 8 x 4,5 x 4,5 mm for 250 V applications and a rated breaking capacity of 100 A. This meets equipment manufacturers' requirements regarding smallest possible unit design.

For the fuse components SIBA has chosen wellknown materials and methods as for the standard fuse program. Thus: the fuse housing is made from high temperature-stable ceramic material; the contacts are of copper alloy with silver or tin surface; the fuse-elements are durable solder connected to the contact caps; high quality manufacturing through fully automated production.

In development, special attention was given to interpretation of the time/current behaviour in the overload and short-circuit range. This electrical behaviour is key in protection design of units. With the philosophy 'Never touch a running system'; the target was to follow the slow-blow characteristic of the widely used miniature fuse-link, and to assign the same operating behaviour to SMD fuse-links.

Really slow-blowing

The SMD fuse-links thus have identical operating characteristics as miniature fuse-links according to IEC 60 127 part 3, which at first view is in contradiction to the standard according to IEC 60 127 part 4 to which these fuse-links comply. Table 1 shows the different characteristic values of the two standards and the rating of the SIBA SMD fuse-links. Whilst the fuse-links according to part 4 are faster in the overload and short-circuit range, the new SMD fuse-link retains the well-known slow-blow characteristic according to part 3.

What is new?

With use of the new SMD fuse-links in dimensions 8 x 4,5 x 4,5 mm, PCBs in the power supply area of the product's transformer can be changed to surface mount production. The fuse-links are suitable for all production methods and optimised for high electrical and mechanical loads. For comparison with existing equipment standards, the fuse-links provide an operating behaviour identical to conventional cylindrical fuse-links and miniature fuse-links. Therefore, recalculations of circuit layouts and/or new electrical tests are unnecessary for the equipment designer.

| Tel: | +27 11 608 3001 |

| Email: | [email protected] |

| www: | www.actum.co.za |

| Articles: | More information and articles about Actum Electronics |

© Technews Publishing (Pty) Ltd | All Rights Reserved