Substantial reductions in both costs and energy consumption can be made by using electronic controls in industrial, commercial and residential use - applications which account for around 70% of all US energy consumption, according to official sources.

Operating motors account for around half of this entire energy bill and many household applications such as dishwashers, washing machines, tumble dryers, heating, ventilation and airconditioning (HVAC) systems use AC single phase induction motors, which are either fully on, or off entirely.

Replacing a standard on/off control with a variable speed motor control when designing such applications could significantly boost energy efficiency and reduce running costs. In the past, this would have added to the complexity of the design, but the inclusion of a microcontroller with a built-in motor control kernel technology can now greatly simplify design and reduce time-to-market for these applications.

Many HVAC systems are obvious examples of applications which either run at full speed or are switched off, with no variation in between. This article aims to demonstrate how designing a variable speed air handler can be greatly simplified by using the reference design available as the programmable motor control processor technology (ProMPT), which is based on Microchip Technology's PIC18F2539 Motor Control Evaluation Kit.

Design overview

Although specifically developed for air handling in an HVAC system, this reference design provides an example of how simplified motor control can be used in other applications. The PIC18F2539 microcontroller in the reference design is an enhanced Flash microcontroller, featuring the single phase induction motor control (SPIMC) kernel. The SPIMC kernel enables open loop variable frequency (VF) control and provides a programmable voltage versus frequency curve and it is a natural choice for adding variable speed control to an air handler application.

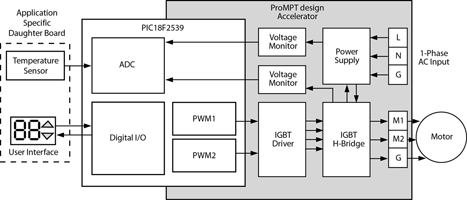

The block diagram in Figure 1 is for the variable speed motor control design. The PIC18F2539 motor control reference design can be used to control shaded pole and permanent magnet split capacitor type motors. Adding specific features can be achieved by designing a custom daughter board. Here, the daughter board adds a user interface and temperature sensor (shown in the dotted lines) to the existing AC induction motor drive.

Application overview

This reference design shows how variable speed control can be added to an HVAC air handler. The application does not address control of the heating element, which is assumed to be a simple logic on/off control. Usually, the thermostat installed within the house sets the target temperature. In this application, a simple user interface consisting of two 8-segment LEDs and two pushbuttons is used to set the target temperature.

The motor control circuit is built around Microchip's PIC18F2539 Flash microcontroller. This microcontroller has an 8-bit RISC core with 24 KB of on-chip program memory and 1,4 KB of data memory available. The peripherals include up to six channels of 10-bit ADCs, two PWM modules, USART, I2C, SPI and up to 20 digital I/Os.

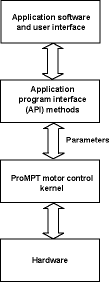

The motor control kernel is embedded in the microcontroller for the user's application development. A set of application program interface (API) methods is used to communicate with the motor control kernel and application software. The application program can be developed, debugged and executed using the MPLAB integrated development environment (IDE) tool.

Temperature sensing

In this design, air temperature is measured using Microchip's TC1047A temperature sensor, a precision temperature-to-voltage converter. This eliminates the need to perform the calibration that is usually required when using thermocouples. The TC1047A is a linear voltage output temperature sensor, whose output is directly proportional to the measured temperature. It accurately measures temperature from -40°C to 125°C, which is more than adequate for household HVAC applications. The temperature sensor requires one analog input pin and supply voltage can vary from 2,5 V to 5,5 V.

When the air temperature is more than 5°C below the target temperature, the air handler operates at full speed and adjusts accordingly when it is within 5° of the target. When the air temperature falls, the air handler speeds up and delivers more hot air into the house.

To avoid on/off cycling when the actual temperature is close to the target temperature, the lower end of the variable speed response curve includes a hysteresis loop. In order for the air handler to turn on at the minimum motor frequency, the actual temperature must be more than 1°C below the target temperature. However, to turn it off, the difference between the two temperatures must be zero. As on/off cycling is avoided, the system is quieter, less obtrusive and energy is conserved.

Single phase motor control kernel

The motor control kernel of the PIC18F2539, or any microcontroller in the family, uses variable frequency technology to control the speed of a single-phase induction motor. The controller's two PWM modules are used to synthesise a sine wave current through the motor windings. The kernel provides open loop control for a frequency range of 15 Hz to 127 Hz.

The speed of an induction motor is a function of frequency, slip and the number of poles in the motor. Slip is assumed to be constant across the motor's useful operating range. Since the rated speed is based on the number of poles and is fixed by motor design, changing the frequency of the supplied voltage is the only way to vary the motor's speed. However, when the frequency controlling a motor is reduced, its impedance is also reduced, resulting in a higher motor current draw.

The voltage applied to the motor is proportional to both the frequency and the current. To keep the current constant at or below the full load current rating, the RMS voltage to the motor must be reduced in line with the frequency. By varying the supply voltage and frequency at a constant ratio, the motor's speed can be varied with constant current. Maintaining this constant ratio is the function of the motor control kernel.

Application firmware

The list below outlines the firmware functions of the variable speed air handler application. Those tasks marked with an asterisk (*) are related to control of the AC induction motor.

1. Initialise the motor control module.*

2. Set the appropriate voltage frequency (VF) curve for the motor.*

3. Execute a continuous loop that performs the following tasks:

a) Read the temperature sensor connected to ADC channel RA0.

b) Read the motor current, DC bus voltage, and heatsink temperature.

c) Read and debounce the button inputs.

d) If a button is pressed, increase or decrease the temperature as necessary.

e) Check for faults.

f) Compare the actual temperature to the target temperature.

g) Set the appropriate motor frequency.*

h) Update the LED display with actual or target temperature.

i) Continuously control the AC induction motor.*

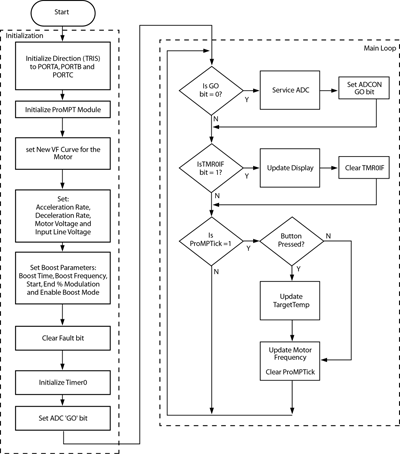

By using the PIC18F2539 and the ProMPT-based Single Phase Induction Motor Control kernel, the biggest tasks are simplified. The ProMPT API methods make the development of the motor control application and its related code much easier. Constants such as motor voltage to frequency curve and acceleration rate are achieved using the appropriate API methods, and are dependent on the specific motor used in the application. A detailed flow chart of the application firmware is shown in Figure 2.

Software interface

A sine table, stored in the ProMPT kernel, is used as the basis for synthesising the DC bus using the PWM modules. The table values are accessed sequentially and scaled based on the motor's targeted operating frequency (speed). The frequency input can be from an A/D channel or a digital value. Parameters in the ProMPT modules can be accessed using the defined API methods.

The kernel memory contains a linear default voltage to frequency (V/F) curve. Users can modify the curve in the application program to meet their requirements using the API method SetVFCurve(X,Y), where X is the frequency and Y is the level of modulation of the DC bus voltage. Normally, the input frequency corresponding to the point on the V/F curve that provides 100% modulation should match the motor's rated frequency. Similarly, full modulation should occur at the motor's rated input voltage.

Using the motor control kernel to develop applications

The motor control kernel enables users to develop applications without having detailed knowledge of motor control. The key parameters of the motor control kernel can be set and read through the application program interface (API) methods. The application can be thought of as a protocol stack, as shown in Figure 3. Here, the API methods reside between the user's application and the ProMPT kernel and are used to exchange parameter values.

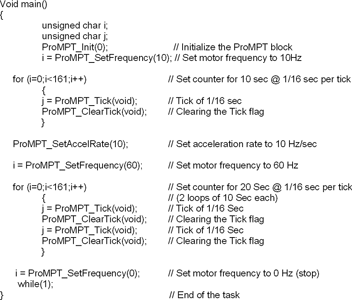

The code shown in Figure 4 shows a typical motor control routine. Here, the motor will run at 20 Hz for 10 seconds, accelerate to 60 Hz at the rate of 10 Hz/s, remain at 60 Hz for 20 seconds, and finally stop. The API methods combined with motor characteristics and applications requirements can be used to run the motor at optimum torque or efficiency, or other criteria.

Conclusion

Variable speed control can easily be added to an HVAC air handler by using Microchip's PIC18F2539 Motor Control Evaluation Kit, greatly simplifying design and reducing time-to-market for many motor control applications. The embedded motor control kernel allows the user with little or no knowledge of motor control, to add variable control to shaded pole and permanent magnet split capacitor type motors, greatly enhancing the end product.

References: Microchip Technology AN861; Microchip Technology PIC18F2539 Data Sheet; ProMPT Developer Kit User's Guide.

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

| Tel: | +27 11 458 9000 |

| Email: | [email protected] |

| www: | www.electrocomp.co.za |

| Articles: | More information and articles about Electrocomp |

| Email: | [email protected] |

| www: | |

| Articles: | More information and articles about Tempe Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved