A group from the Hermanus Magnetic Observatory in the Western Cape was named as one of the winners at the 4th Annual PC/104 Embedded Design Contest awards function held in San Jose, California.

The product is a first for South Africa and, to the developer's knowledge, there is no similar system in the world. The Magnetic Test Bench team, which comprises Danie Gouws (designer, project manager); Herman Theron (software and electronic engineering); David Wright (mechanical engineering), developed and built the magnetic test bench (MTB), a new product for compass calibration in the aerospace industry.

The development team used a product designed by Electronic Products Design, a local industrial computer company, amongst the others that they purchased from the company, for example, Diamond Systems' A/D card and the rugged Tri-M CanTainer.

Background

The South African Air Force often encountered problems during compass swings - a procedure used for the in-situ calibration of aircraft compasses. Maintenance staff executing compass swings, often found that reconditioned compasses, issued from stores prior to installation in the aircraft, were unserviceable, causing serious compass swing problems and the unproductive use of aircraft engine hours.

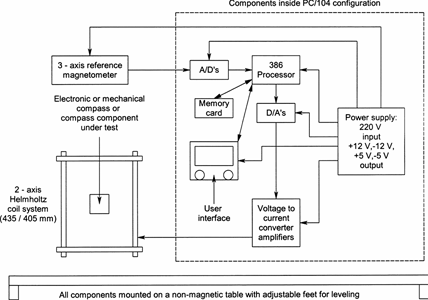

The MTB solves this problem with the calibration and verification of mechanical and electronic aircraft compasses on a stationary test bench prior to their installation in aircraft. The system accurately measures the ambient magnetic field, and executes algorithms to supply the required current to a specialised 2-axis Helmholtz coil system for the generation of a magnetic field of a predetermined strength and direction. The compass or compass component under evaluation are fixed in the MTB coil system (which is outside the aircraft), and the generated magnetic field is rotated in user-selectable steps through 360°, simulating an aircraft compass swing.

The system reduces the running cost of aircraft drastically, by reducing the unproductive use of airframe and engine hours, aircraft fuel and labour during problematic compass swings. By using the MTB, the turnaround time for aircraft under compass maintenance is significantly reduced. The system, also, does not require a highly skilled operator.

The MTB received the following awards during 2005:

* SA Design Excellence Award 2005 from the Design Institute of South Africa (a division of the SABS).

* August 2005 monthly winner in the SA Popular Mechanics' 'Great South African Inventors Competition'.

* 2005 Centre for Public Service Innovation Award, category: Enhancement on Internal Systems within Government.

The design problem and PC/104 solution

As time was of the essence, an important requirement was a brief learning curve for the system designer on the processor and data acquisition units. Furthermore, in-depth knowledge of microprocessors was undesirable as a prerequisite for the development and future maintenance of the MTB. On-board auto-calibration functions for the A/Ds and D/As were very important to reduce calibration maintenance of the system.

Low cost, reliable components were required that could operate in dusty environments where vibrations (from aircraft or other equipment) may be present. Given the magnetic field application of the product, the DC magnetic signature of all sub-systems needed to be as small as possible. Both the standard user interface used by the operator, as well as a hidden menu used for invoking specialised functions required during the integration, alignment and verification of each system, should be accessible using only a four line LCD and two pushbuttons.

All of the above requirements were well met by the PC/104 methodology and components. Although the original specification requested a 1 standard deviation (1s) accuracy of 2°, the production models, containing these PC/104 components, have a consistent 1 s accuracy of 0,6°.

PC/104 products used included:

* Acrosser Technology's AR-B1320 compact 386 SX processor, with SanDisk memory card.

* Diamond Systems' MM-AT auto-calibrating 12 bit A/D and D/A data acquisition unit.

* Power supply designed and built by Electronic Product Design - 220 V input, ±5 V, ±12 V output in PC/104 format.

* Voltage-to-current amplifiers in PC/104 format designed and constructed by the Hermanus Magnetic Observatory.

* Tri-M CanTainer 104 enclosure.

* SuperVGA controller from Avance Logic (only during development).

According to the design team, their choice of PC/104 technology was mainly because of its benefits of: compact size, expandability, low power, ruggedness, low cost. Other advantages are its low DC magnetic signature, and protection against vibration and dust.

For more information contact Jaap Willemse, Electronic Products Design, +27 (0)12 665 9700, [email protected] or Danie Gouws, HMO, +27 (0)28 312 1196, [email protected]

| Tel: | +27 12 493 0852 |

| Email: | [email protected] |

| www: | www.epd.co.za |

| Articles: | More information and articles about Electronic Products Design |

© Technews Publishing (Pty) Ltd | All Rights Reserved