Before reaching a consumer, perishable products like food and medicines spend a significant time in transportation, and then on shelves of large refrigeration units. It is important that these products reach the end-consumer in a fresh and viable condition, so that their nutrients and efficacy are maintained.

To ensure quality and product safety, manufacturers specify the temperatures at which items must be transported and stored.

Cold chain management and Good Distribution Practices (GDP) ensure that the correct conditions are met during every phase of the lifecycle of packaged and perishable goods. It also ensures that, should a possible deviation from the normal temperature occur, an appropriate action be taken by the operator either during transportation or during storage to make sure that minimal wastage occurs.

Cold chain topologies

The use of temperature sensors utilising gauges and simple analog sensors has largely been the norm. However, with advances in semiconductor technology and the fact that most cold chain management is done in the temperature range of -40° to 10°C, integrated temperature sensors are the best option for management in this range.

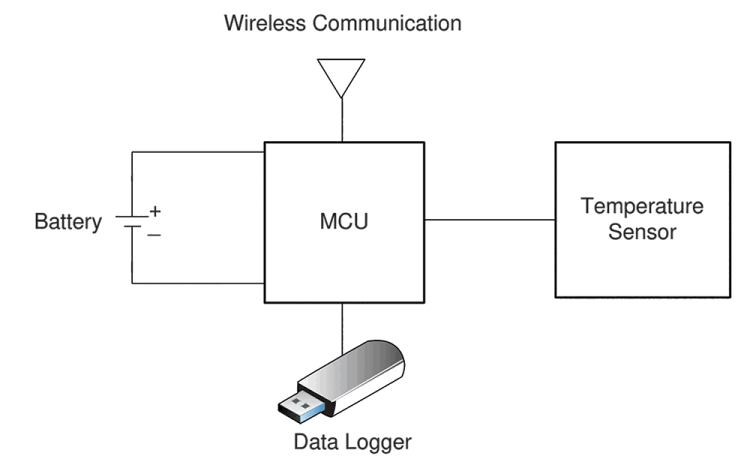

Based on the application, there are different topologies that may be deployed. In a point-to-point topology (Figure 1), a single microcontroller unit (MCU) is connected to a temperature sensor that may have either an analog or a digital output. Texas Instruments’ TMP116 temperature sensor operates from -55°C to 125°C, and has a 0,2°C accuracy in the range -10°C to 85°C.

The sensor integrates I2C and SMBus-interface communication, as well as an integrated EEPROM. Calibration is not required, and the device consumes minimal current, which minimises self-heating. With its maximum 16-bit conversion, the TMP116 is typically used in applications with a focus on high accuracy.

This point-to-point topology is useful when monitoring a temperature-controlled container during transport, but when the application requires multiple sensors like in reefer containers, the cost of a single MCU is too high to be implemented multiple times throughout the system. In this case, the most common topologies are either a star, a daisy chain or a shared bus, where one MCU is the host controller for multiple sensors. A star topology allows for easy fault isolation and may use both analog and digital temperature sensors. This topology, however, has a higher cost of implementation as the controller peripheral count is higher.

With a shared bus, the scalability can easily be addressed with a digital temperature sensor that shares the line and may be individually addressed like in the case of I2C communication, or out-of-band signalling using chip select as is the case with SPI communications. This topology does, however, raise the concern for reliable power delivery and signal integrity over a long chain.

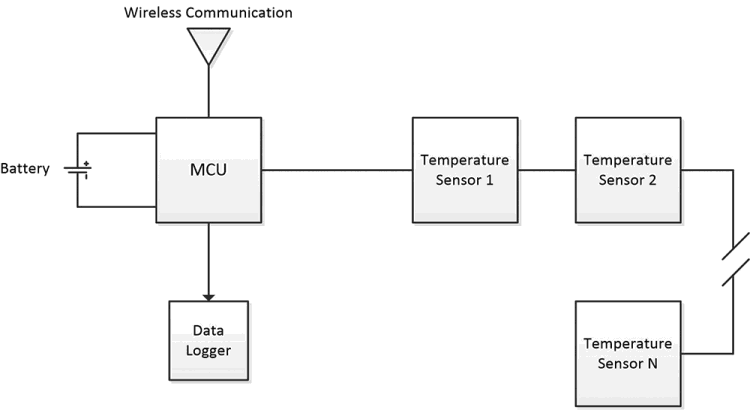

The daisy chain topology (Figure 2) does not require out-of-band signalling but rather uses an in-band addressing scheme. Each stage of the chain acts as a buffer for the next stage, which maintains signal integrity over longer distances.

Irrespective of which stage is being monitored, electronic systems provide a unique advantage of not only logging the temperature of the refrigeration unit, but also providing thresholds above which an alert is generated. These alerts can be communicated visually or audially through an LED or buzzer, but they can also be integrated into cloud services using either a wired or wireless MCU, allowing round-the-clock remote monitoring and data logging.

Daisy chain topology in cold chainmanagement

The TMP107 is a digital temperature sensor that supports up to 32 daisy-chained devices and is ideal for replacing older NTC and PTC thermistors in cold chain management where high accuracy is required. The sensor has a maximum accuracy of 0,4°C in the range from -20°C to 70°C and 0,55°C in the extended range of -40°C to 100°C, with a temperature resolution of 0,0156°C.

With an automatic address assignment, the TMP107 allows developers to write software without the need to assign an address at each sensor node as the system is scaled upwards. The system is made more resilient against any noise which may affect the temperature value over long cable spans by using push-pull communication I/O. This allows for data transfers over distances of 300 metres between adjacent devices in the chain. A daisy chain implementation also makes it easier to identify the location of a cable break, thereby making maintenance simpler and improving overall system reliability.

When performing temperature conversions with the active bus communication, the current consumption of the TMP107 is typically 300 µA, while it has a shutdown current of only 3,8 µA in low-power mode. This low current consumption, together with a wide operating voltage of 1,7 V to 5,5 V, makes this sensor ideal for battery-operated systems during the transport phase of cold chain management.

The sensor’s internal non-volatile memory allows for the storage of the configuration and temperature limits. This allows the device to be automatically configured during power-up, eliminating the need for it to be individually configured, thereby making the system operate faster. The device also has eight EEPROM locations providing up to 128 bits to store user or calibration information.

While the TMP116 has better accuracy and is ideal for monitoring a single location, the TMP107 has the right combination of accuracy, power consumption and features to support a battery-based cold chain management system where multi-point monitoring is needed.

© Technews Publishing (Pty) Ltd | All Rights Reserved