One of the most exciting low-power wireless technologies to emerge in the last couple of years is Bluetooth beacon technology, which involves placing small electronic beacon devices at points of interest that broadcast packets of information via Bluetooth low energy to the smartphones of passers-by.

These packets of information can be used to help the smartphone determine where it is, since the location of the beacon is known, which can be useful for navigating around indoor areas like airports and shopping malls where GPS isn’t available.

The other major use case is retail advertising, whereby a beacon placed within a display for a certain product broadcasts a coupon or offer code for that product to the smartphone of a user who is lingering at that particular display. There are many hundreds more use cases for Bluetooth beacons but these are probably the most popular for this technology to date.

Fitting a Bluetooth beacon in a retail environment or airport must of course involve consideration of how the device will be powered. Mains power may be available for new installations, but more often than not it is easier and more convenient to have the beacon powered by small batteries.

Batteries mean the devices can be installed instantly, and moved whenever required, and Bluetooth low energy technology, combined with today’s battery technology, means it may be months or years before the batteries need replacing.

The first thing to consider when selecting a battery for a Bluetooth beacon design is whether to go with primary chemistries (non-rechargeable) or rechargeable types. For primary battery solutions, the batteries’ capacity and longevity is obviously of paramount importance to avoid costs incurred when replacing them, including both the cost of the new batteries and the labour cost associated with changing them – this may seem small but if an airport has hundreds of beacons installed for indoor navigation it quickly becomes significant. If beacons are deployed in remote or inaccessible locations this problem is compounded. Replacement costs also apply to rechargeable batteries that may have failed for whatever reason; reliability is therefore crucial for both battery types.

Both primary and rechargeable batteries will need to work across a wide operating temperature range, and rechargeables will need to be able to recharge at these temperatures too. For industrial applications, this might mean operating at up to 85°C, though some indoor applications (particularly in confined spaces) also get very hot.

If it’s outdoors, it will need to work in negative temperatures and when the weather is humid. Another key consideration is the physical size of the batteries. Beacons are compact devices, designed to be fitted in small spaces, and they also have to look unobtrusive. This means that both batteries’ size and their power density/energy density are important.

The electrical considerations for different types of batteries include the voltage they can provide. Higher-voltage batteries are usually deemed more desirable as it may be possible to use fewer cells than an equivalent solution using lower-voltage types. The current that the batteries can provide at their peak discharge level is a useful measure of whether they can provide enough power for your application.

Other characteristics to look out for include self-discharge figures; for long-life applications like beacons, we need something without much self-discharge as we want the batteries to last for a long period of time. If your application recharges its batteries in situ, perhaps from a solar panel mounted on the beacon or some other form of energy harvesting, the battery must be able to accept a wide range of recharging voltages and currents from the energy harvesting solution, and be able to use the tiny amounts of energy these solutions provide.

Primary chemistries

Batteries’ mechanical and electrical properties are in large part dependent on their different chemistries.

The most widely used primary chemistry in consumer electronics devices is alkaline, but these are unlikely to suit beacon applications as they simply don’t last long enough. Their low cost and wide availability from convenient locations such as supermarkets is offset by the number of times alkaline batteries will need to be changed over the life of the product. They are also low-voltage (typically less than 1,5 V) and have a limited temperature range of 0°C to 60°C.

The major alternative to alkaline for primary batteries is chemistries based on lithium. Lithium cells have the highest available energy density and provide relatively high voltages, between 2,7 and 3,6 V dependent on their exact chemistry.

One of the most popular lithium chemistries is lithium iron disulphate (LiFeS2), as it’s relatively inexpensive and can deliver high pulse currents. Lithium manganese dioxide (LiMnO2) batteries are also widely used in consumer electronics, particularly in compact applications, as they can provide 3 V (enough to replace two 1,5 V alkaline batteries). However, both these chemistries’ temperature range is just -20°C to 60°C and they have a relatively high self-discharge rate.

Lithium thionyl chloride (LiSOCl2) cells are a more expensive choice than some of the other lithium chemistries, but they offer the highest energy density of all. They have several other advantages, including very long battery life, even under extreme temperature and humidity cycles.

Lithium thionyl chloride devices can typically operate at -40°C to +85°C, but those made with the most robust bobbin construction (such as in Figure 2) can withstand up to -80°C to 125°C in some cases. They can last between 10 and 40 years, dependent on the quality of the raw materials and construction. Self-discharge can be as low as 0,7% per year, ideal for remote applications such as beacons.

A great example is Tadiran’s PulsesPlus series of lithium thionyl chloride batteries (Figure 3), which provide 3,6 V with only 0,7% self-discharge, ideal for Bluetooth beacon applications. Five models provide a choice of capacity between 2,5 and 38 Ah, and they can support high pulse current for transmission of RF signals.

Rechargeable chemistries

Rechargeable chemistries include nickel metal hydride, lithium ion and lithium polymer. Of these, consumer grade lithium-ion batteries are the most widely used today; they last up to five years if charged correctly and have an operating temperature range of -10°C to 60°C, which may suit a beacon application. Lithium polymer batteries, like the types used in smartphones, are primarily lauded for their thin form factor as they can be made in sheets.

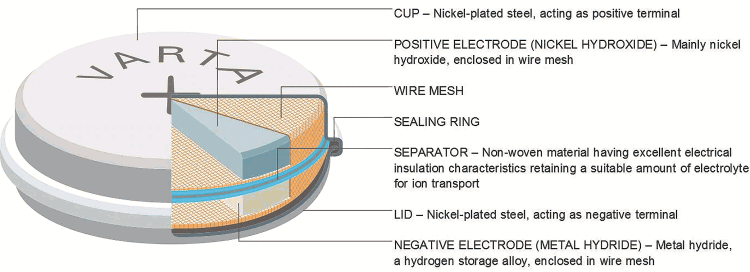

Some modern nickel metal hydride (NiMH) cells, such as the Robust85 series from Varta, are reliable enough for beacon applications. Their temperature range is -25°C to 85°C, they last five years at 45°C, and can offer anywhere between 1,2 and 4,8 V to the application. Compared to lithium chemistries, their charging requirements are relatively simple, allowing continuous charging as the risk of overcharging is low.

Ultimately, the exact battery choice for a successful Bluetooth beacon design will depend on the exact nature of the deployment but, broadly speaking, lithium thionyl chloride and rechargeable nickel metal hydride batteries offer the best energy densities combined with longevity, reliability and cost effectiveness.

Avnet Abacus carries a wide range of both types from specialist suppliers including Tadiran, Varta, and many more. If you have specific battery requirements or would like to discuss your design in more detail, get in touch with local representative, Avnet South Africa.

© Technews Publishing (Pty) Ltd | All Rights Reserved