Solar energy, once the preserve of advanced spacecraft and select novelty gadgets, has undergone a remarkable transformation. Over the past decade, it has shifted from a niche power source to a fundamental pillar of the global energy landscapes.

The Earth continuously receives about 173 000 terawatts (TW) of solar radiation, more than ten times the average global electricity demand. This means solar energy has the capacity to fulfil all our energy needs.

In the first half of 2023, solar energy’s contribution rose to 5,77% of the total US electrical generation, compared to 4,95% in 2022. While fossil fuels – mainly natural gas and coal – were responsible for 60,4% of the US energy generation in 2022, the growing influence of solar energy and the rapid advancements in solar technology are noteworthy.

Types of Solar Cells

Currently, three main categories of solar cells, also known as photovoltaic (PV) cells, exist in the market: crystalline, thin film, and newer technologies. Each has strong efficiency, cost, and longevity performance factors.

Crystalline

Most home roof-mounted solar panels are made of high-purity monocrystalline silicon. This cell type has recently achieved efficiencies exceeding 26% and 30+ years of durability. In practice, the best efficiency available today for a home is about 22%.

Multicrystalline silicon is less expensive than monocrystalline but has lower efficiency and shorter lifetimes. The lower efficiency means more panels and, therefore, more area is needed.

Solar cells based on multi-junction gallium arsenide (GaAs) technology offer higher efficiency compared to conventional solar cells. These cells use layers of different materials, such as gallium indium phosphide (GaInP), indium gallium arsenide (InGaAs), and germanium (Ge), with each layer designed to absorb various wavelengths of sunlight. Despite their promising efficiency, these multi-junction cells face challenges in terms of high manufacturing costs and the need for further research and development, which currently limits their commercial viability and practical application.

Thin film

The primary thin film product on the global market is the cadmium telluride (CdTe) PV module, with many millions of these modules installed worldwide, offering more than 30 GW peak generating capacity. However, concerns exist over the toxicity of cadmium and the availability of telluride. In this thin-film technology, a 1 m2 solar module has a lower cadmium content than that of a AAA-size nickel-cadmium (Ni-Cd) battery. Furthermore, the cadmium within the solar module is bound to tellurium, which is insoluble in water and stable up to 1200°C. These aspects mitigate the toxicity hazards of using CdTe in thin-film cells.

Tellurium is present in the Earth’s crust only in about 0,001 parts per million. Similar to the rarity of platinum in the Earth’s crust, this factor significantly impacts the cost of a CdTe module. However, recycling may positively affect the scarcity of tellurium.

CdTe modules offer efficiencies up to 18,6%, with lab cell efficiency above 22%. Replacing longstanding copper doping with arsenic doping results in much better module lifetimes that are comparable to crystalline cells.

Emerging technologies

Emerging PV technologies that use ultra-thin films (less than 1 μm) and straightforward deposition techniques are set to lower production costs and deliver high-quality semiconductors for solar cells. These are seen as potential rivals to established materials like Si, CdTe, and GaAs. Three notable thin film technologies in this realm are copper zinc tin sulfide (Cu2ZnSnS4 or CZTS), zinc phosphide (Zn3P2), and single-walled carbon nanotubes (SWCNT). In laboratory settings, copper indium gallium selenide (CIGS) solar cells have achieved impressive efficiency peaks of 22,4%. However, replicating these efficiency levels on a commercial scale remains a challenge.

The most prominent emerging solar technology is lead halide perovskite thin-film cells. Perovskites are a class of substances with a crystal structure having a typical chemical formula ABX3. It is a yellow, brown, or black mineral consisting mainly of calcium titanate (CaTiO3). A commercial-sized perovskite-on-silicon tandem solar cell from Oxford PV in England yielded a record efficiency of 28,6% and is in production as of this year.

In just a few years, perovskite solar cells have achieved efficiencies similar to those of established CdTe thin film cells. Lifetime was a big problem in early perovskite R&D, measured in months. Recent modifications have extended the lifetime to 25 years or more. Current perovskite solar cells have a high conversion efficiency (over 25%) and low production costs at low temperatures.

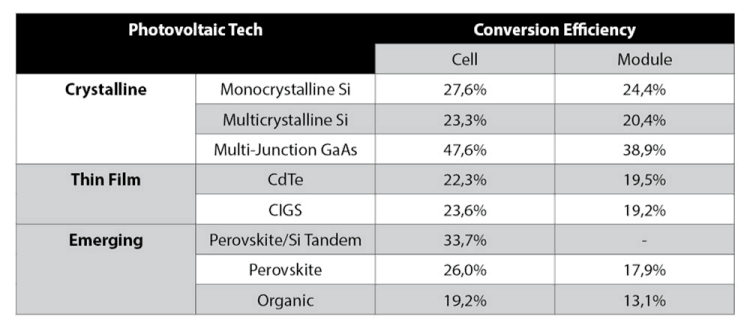

Table 1 shows the conversion efficiencies of the main cell categories through laboratory R&D; testing.

Building integrated solar panels

Certain solar cells are designed to capture only a portion of the solar spectrum, while allowing visible light to pass through. Known as dye-sensitized solar cells (DSCs), these transparent cells were invented in 1991 in Switzerland. With the latest R&D; making DSCs more efficient, it may not be long before these solar panels are on the market.

Some companies use inorganic nanoparticles infused in a polycarbonate interlayer of the glass. Nanoparticles in this technology divert specific parts of the light spectrum to the glass’s edge, permitting most of the spectrum to pass through. The light gathered at the glass edges is then harnessed by solar cells. Additionally, there is ongoing research into the use of perovskite thin film materials for applications in transparent solar windows and building exteriors.

Required raw materials for solar

To boost solar power production, there will be an increased demand for mining essential raw materials like silicon, silver, copper, and aluminium. The US Department of Energy notes that approximately 12% of the global production of metallurgical-grade silicon (MGS) is processed into polysilicon for solar panels.

China is a major player in this sector, producing about 70% of the world’s MGS and 77% of the global polysilicon supply in 2020. The process of transforming silicon into polysilicon requires extremely high temperatures. In China, these processes are powered predominantly by coal. Xinjiang, a region known for its abundance of coal and low electricity costs, accounts for 45% of the world’s polysilicon production.

Solar panel production consumes approximately 10% of the world’s silver. Silver mining – carried out primarily in Mexico, China, Peru, Chile, Australia, Russia, and Poland – can lead to issues such as heavy metal contamination and displacement of local communities.

Copper and aluminium mining also present land-use challenges. The United States Geological Survey agency states that Chile is responsible for 27% of the world’s copper production, followed by Peru (10%), China (8%), and the Democratic Republic of Congo (8%). The International Energy Agency (IEA) suggests that in a scenario where the world shifts to 100% renewable energy by 2050, the demand for copper in solar energy projects could nearly triple.

Conclusion

Will solar energy someday be our primary source? Prices are going down; efficiencies are up, but there are many different technologies to select from. When will we decide on just one or two and plow forward to make it really work? How will it be integrated into the grid – or not?

Solar energy’s evolution from a specialised to a mainstream power source highlights its vast potential to meet and exceed our energy needs. While crystalline solar cells currently dominate the market, advancements in thin-film and emerging technologies, like CdTe and perovskites, pave the way for more efficient and integrated solar applications. Challenges remain, such as the environmental impact of raw material extraction and production bottlenecks, but the sector’s rapid growth and innovation are promising.

With the right balance of technological advancement and sustainable practices, solar energy stands as an encouragement for a clean, abundant energy future, mirroring its significant growth in the US energy mix and showcasing its global potential to be a sustainable solution.

For more information visit www.mouser.com

© Technews Publishing (Pty) Ltd | All Rights Reserved