Industry-specific housing solutions are placing new requirements on both electronics development and the electronics housings themselves. At the same time, system solutions are playing an increasingly important role. The building automation specialist, Neuberger, uses modular electronics housings for I/O applications from Phoenix Contact for its new controller (Figure 1).

Room automation for less energy consumption and added convenience

Neuberger Gebäudeautomation GmbH, from Rothenburg ob der Tauber, Germany, is a leading provider of systems for building automation. Currently, room automation has become a dominant topic for planners and operators of office buildings, hotels, schools and clinics. Convenience for the user isn’t the only focus when temperature, lighting, surveillance, and many additional functions need to be controlled and regulated individually. Topics such as energy efficiency, added convenience, and cost optimisation are becoming increasingly important for operators and users.

In 2015, Neuberger began to develop a new room automation system, and was looking for a new housing system for this purpose. The main requirement was the need to be able to connect many cables by means of front connection, and with the now widely-used Phoenix Contact ‘Push-in’ connection technology. Additional requirements for the housing system were a high level of modularity for the housing variants, and a DIN rail connector.

Cooperation began in 2015

That fit well with the fact that Phoenix Contact, as a leading provider of empty electronics enclosures, had just launched a brand-new product family with front connection technology. While searching for a suitable housing system, the Neuberger developers also sought information at the Phoenix Contact stand at the Embedded World trade fair in Nuremberg in 2015.

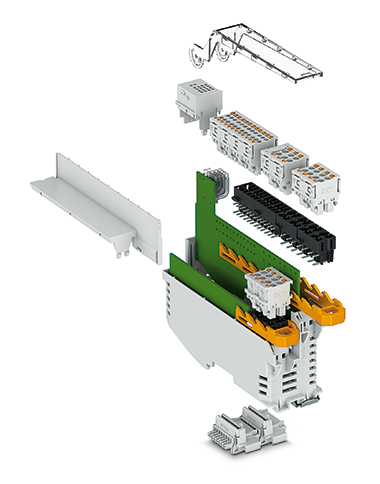

There, the requirements that had already been precisely defined by Neuberger were compared with the functions of the new housing system. When a large overlap became apparent relatively quickly, a close cooperation was established. With Neuberger as a key customer and the specified requirements of the new room automation system, Open.Room, the front connection technology housing was adapted successfully to the requirements of the joint project (Figure 2).

One of the special features of the new ME-IO housing system is the connection technology on the front, which is based on the Push-in connection and, like many other components from Phoenix Contact, is now widely used. Wiring is convenient and tool-free, thanks to the push-in spring-force connector – an advantage over the conventional screw or spring-cage connection. This is because with the Push-in connection, a special contact spring ensures high contact and conductor pull-out forces and vibration-proof contacting. The front connection technology allows easy access to the Open.Room modules.

The codable PCB connectors can be released easily via the established ‘Lock and Release’ technology. To do so, the plugged-in connection blocks are released and lifted out of the header by actuating a single trip lever; this allows them to be removed easily from the plugged-in position in a de-energised state, ensuring error-free device replacement.

Five types of front connectors are available for the selection and configuration of the connection technology. They can be combined with each other as needed. This allows you to arrange a mixture of 4-position and 6-position connection blocks. With terminal blocks for higher voltages, it is possible to separate connection blocks with lower voltage ranges. The connection blocks and the actuating elements for the Push-in connection are available in different colours and can be arranged however the customer likes. For the 6-position connection elements, up to 54 connections with a width of 18,8 mm are available (Figure 3).

The ME-IO housing system provides numerous application options, and not just because of its modular principle. If the housing modules are first configured in accordance with the requirements of the device manufacturer, communication between several modules can be realised conveniently via a DIN rail connector. The DIN rail connector is snapped into the standardised DIN rail; the individual I/O modules on the ME-IO housing system can then be opened unchanged on the DIN rail with the locked bus connectors and are immediately interconnected securely.

The DIN rail connector is available as a 5-position and an 8-position version – each with three different contact assignments. The 8-position design is available in variants with 8 parallel contacts, 7 parallel and 1 serial contact, and 6 parallel and 2 serial contacts.

Thanks to these features, the ME-IO housing system was examined more closely by Neuberger for the development of room automation systems. After a series of customer-specific adaptations, which Phoenix Contact was able to implement in numerous customer projects due to its expertise, the housing was selected.

Creating the target system

Controlling and regulating complex buildings requires a flexible, future-proof, and intelligent room automation system. The Neuberger room automation system Open.Room fulfils all functions of room automation – from lighting, surveillance, presence and media technology, all the way to room climate control. With the newly developed room automation based on the ME-IO housing, a system is made available to operators that comprises a CPU module, input and output modules, and communication modules.

Summary

In the search for a suitable housing for its newly developed room automation system, Neuberger chose the ME-IO housing system. The arrangement and number of modules in ME-IO housings are flexible, so all modules of Open.Room can be combined with one another.

Wiring is fast and simple and requires no tools, thanks to Push-in connection technology. The simple locking system allows the modules to be replaced quickly if needed, and operation continues without problems during the process. The current status of the building automation system is shown by LEDs on the front of the housing, which are clear and visible at a glance. The compact design of the Open.Room module stored in the housing allows space-saving installation and assembly on DIN rails, which is ideal for use in ceiling, wall and floor distributors.

| Tel: | +27 11 801 8200 |

| Email: | [email protected] |

| www: | www.phoenixcontact.co.za |

| Articles: | More information and articles about Phoenix Contact |

© Technews Publishing (Pty) Ltd | All Rights Reserved