Elektro-Automatik’s new series of electronic DC loads with energy recovery to mains, called EA-ELR 9000 HP, is an advancement of the series EA-ELR 9000. It offers a wider AC input range for operation on industrial grids with 380 V, 400 V or 480 V three-phase supply. Furthermore, all models offer a higher power rating and there is a new voltage class for 0-360 V. The insulation of some high-voltage models has also been improved.

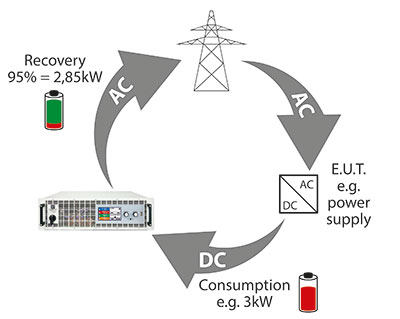

The energy recovery function converts the supplied DC energy into a synchronous sine current and feeds it back into the local grid, reducing the usual heat dissipation to a minimum and saving energy costs at the same time. The large colour TFT touch panel offers a different and intuitive kind of manual operation.

All models require a 2-phase or 3-phase mains supply without N conductor, as is typical in industrial grids. The devices offer a wide range AC input with 342-528 V a.c., covering common international grid ratings between 380 V and 480 V.

Energy recovery

The most important feature of these electronic loads is that the AC input, i.e., grid connection, is also used as output for the recovery of the supplied DC energy, which will be converted with an efficiency of up to 95%. This way of energy recovery helps to lower energy costs and avoids expensive cooling systems, such as those required for conventional electronic loads which convert the DC input energy into heat.

Operation of these recovering loads in terms of power generation is not intended. Grid protection devices, which could supervise the feedback of energy into the public grid, are available on the market for optional installation and are intended to achieve additional safety of persons and equipment, especially when running the so-called isolated operation. But such a device would usually require the N conductor.

Regardless of whether the user has installed such a supervision unit or not, the devices feature a simple and non-redundant switch-off function for the case of an interruption in the grid connection cable. The device supervises AC voltage and frequency and will automatically switch off the power stages in case upper or lower limits are exceeded.

Function generator and table control

A special feature is the comfortable, FPGA based digital function and arbitrary generator. It enables the user to control and run user-customisable load profiles and can generate sine, square, sawtooth and ramp functions in arbitrary order.

With a freely programmable, digital value table of 3276 points, which is embedded in the control circuit, the devices can reproduce non-linear internal resistances, such as those of batteries or LED chains. For purposes of testing all kinds of batteries, such as for example constant current or constant resistance discharging, the devices offer a battery test mode.

Battery test

For the purposes of testing all kinds of batteries, such as for example constant current or constant resistance discharging, the devices offer a battery test mode. This shows extra values for elapsed testing time and consumed capacity (Ah).

Data recorded by a PC during tests with, for example, EA Power Control, can be exported as an Microsoft Excel table in CSV format and analysed later in Excel or similar tools and even visualised as a discharge diagram. For more detailed setup, there is also an adjustable threshold to stop the battery test on low battery voltage, as well as an adjustable maximum test period.

Master-slave

All models feature a digital master-slave bus by default. It can be used to connect up to 32 units of identical models in parallel operation to a bigger system with totals formation of the actual value of voltage, current and power.

The configuration of the master-slave system is either completely done on the control panels of the units or by remote control via any common digital communication interface. Handling of the master unit is possible by manual or remote control (any interface). Alternatively to the standard models, there are specific slave models available.

Share Bus

The so-called ‘Share Bus’ is an analog connection at the rear of the devices and is used to balance current across multiple similar units in parallel connection, such as with loads of this series and series EA-ELR 9000. It can also be used to build a two-quadrant system in connection with power supplies of series EA-PSI 9000 or EA-PS 9000. This system is dedicated to testing purposes using the source-sink principle.

Remote control and connectivity

For remote control, there are by default two interface ports (1x analog, 1x USB) available on the rear of the devices, which can also be extended by optional, pluggable and retrofittable digital interface modules (dedicated slot).

Alternatively to the interface modules slot, all models can be equipped with a three-way interface, which then offers 1x GPIB/IEEE488, 1x USB and 1x analog on the rear side of the device.

For implementation into the LabView IDE, Elektro-Automatik offers ready-to-use components (VIs) to be used with the interface types USB, RS-232, GPIB or Ethernet. Other IDEs and interfaces are supported by documentation about the communication protocol.

Windows users can profit from the free software EA Power Control. It offers a feature called ‘sequencing’, where the device is controlled through a semi-automatic table in CSV format. This table represents a simple test procedure and can be created and edited in Microsoft Excel or other CSV editors and then imported into the software tool. This software also allows for the control of up to 20 units at once, with an optional feature called ‘Multi Control’ (licensed, not free of charge).

| Tel: | +27 11 454 8053 |

| Email: | [email protected] |

| www: | www.vepac.co.za |

| Articles: | More information and articles about Vepac Electronics |

© Technews Publishing (Pty) Ltd | All Rights Reserved