If you use a smartphone you are using a touchscreen. Many shopping centres have touchscreen information displays. Touchscreens in industry and on desktops are also becoming more common. What are the technologies involved and which is the best for your next innovative application?

There are five main touchscreen technologies, of which two are becoming the most commonly used:

• Resistive touch – low cost and very commonly used.

• Surface capacitive – popular, requires skin or stylus contact.

• Projected capacitive – increasingly popular, multi touch, can be used with thin gloves (popular in the medical field).

• SAW touch – older technology, has disadvantages.

• Infrared (IR) touch – high clarity but has disadvantages.

Resistive, SAW and IR touch were the early technologies developed. SAW and IR were both more expensive and had technical disadvantages such as sensitivity to dust, light interference and dust or grease build-up on the screen. Resistive touch is lower cost and resistant to surface contaminants but can be damaged by scratching or sharp objects. Capacitive touchscreens are more durable than resistive screens and offer greater resistance to surface contamination. They also have better clarity than resistive screens.

The main advantage of projected capacitive over surface capacitive screens is that they offer multitouch capability. This gives application developers and users facilities such as zooming of screens and pictures.

When considering which technology to choose for your next application, consider the following:

Cost – Resistive touchscreens are lower cost.

Durability – Capacitive touchscreens are more durable.

Clarity – Not necessarily the most important, but capacitive screens offer higher clarity.

Multitouch – Not many current business or industrial applications require multitouch but one should always be looking to the future. Perhaps you can make your application stand out over the competition by introducing multitouch.

User acceptance – Every user of a smartphone uses a touchscreen and in most cases a multi-touchscreen. Upgrading current applications to multitouch could increase the acceptance of applications and the ease of use for end users.

As technology improves and becomes smaller, smarter and part of everything we use, touchscreens are becoming more and more common. Cellphones are probably the most commonly used item. Other commonly used applications are the information displays in shopping centres and the credit card machines at points of sale. The Internet of Things (IoT) promises to make the use of touchscreens more common as they get built into refrigerators and other appliances.

In industry, the use of touchscreens on production lines is improving the gathering of production information. By allowing developers to provide applications that end users on the production line can use to select options and give feedback on things like stoppage reasons, management is better able to analyse and improve production methods.

In dirty, dusty environments, users wearing heavy industrial gloves can operate a touchscreen easily. A keyboard would require the removal of gloves and keyboards have to be very robust to survive in most industrial environments.

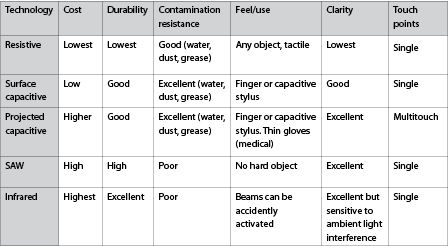

The table compares the various touch technologies.

Centurion Micro Electronics can provide an excellent range of touchscreens and panel PCs from 6 inches to 24 inches using resistive and projected capacitive touch technologies and with IP ratings up to IP67.

For more information contact Henry Hugo, Centurion Micro Electronics, +27 (0)83 581 4549, [email protected], www.cme.co.za

| Tel: | +27 12 666 9066/8 |

| Email: | [email protected] |

| www: | www.cme.co.za |

| Articles: | More information and articles about Centurion Micro Electronics |

© Technews Publishing (Pty) Ltd | All Rights Reserved