Many fractional horse power (FHP) motor manufacturers, selling to the appliance, heating, ventilation and air conditioning equipment industries, are seriously evaluating a switch from copper to aluminium magnet wire. The economics of switching to aluminium are quite straightforward: copper magnet wire currently contributes up to 10% to the overall cost of a typical FHP electric motor. At current market prices, switching from copper to aluminium wire can potentially reduce this contribution to less than 2%.

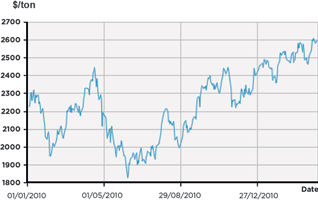

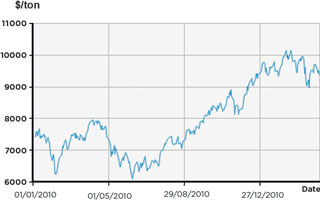

However, to achieve equal conductivity, aluminium wire needs to have a larger cross sectional area than copper. As a rule the AWG has to be reduced by two numbers which means that, for instance, a #20 AWG copper wire could be replaced by #18 AWG aluminium wire. Yet, even on an equal conductivity basis, aluminium is one half the weight of copper. For medium- and high-volume FHP motor manufacturers in particular, the reduced material cost and the lower motor weight are equally welcome. Looking at the price development, it also appears that aluminium is not subject to the same price increases that can be seen with copper.

Advantages of aluminium magnet wire include:

* Aluminium is traditionally 1/4 the cost of copper.

* Aluminium is 1/3 the weight of copper.

* Aluminium is 1/2 the equal conductive weight of copper.

* Aluminium is 1/8 the cost per unit of conductivity vs. copper.

* Between March 2010 and March 2011 the copper price increased 30%, while the aluminium price increased only 12% over the same period.

Wire connection technology has to be on a par with the reliability of copper-based interconnection

The major obstacle to benefiting from the huge potential cost savings has always been finding a way to make electromechanical connections to aluminium magnet wire at production and reliability levels equal to that of copper magnet wire. This article takes an in-depth look at the above opportunities and obstacles and offers solutions to reconcile the two. As aluminium is more brittle than copper, the interconnection needs to be adjusted for its different material properties. Still, the termination technology needs to be fast, efficient, durable and repeat-accurate which more or less excludes sonic welding or soldering from the list of options for medium- to large-volume production.

IDC technology

TE Connectivity has been successfully driving a superior solution for magnet wire termination over the past 15 years. Many leading FHP motor and pump manufacturers around the world use the company’s MAG-MATE product range to terminate copper magnet wire. This product portfolio is based on insulation displacement connection (IDC) technology, which has proven to be an effective alternative to stripping and soldering wire in thousands of applications for over 40 years.

Originally the IDC principle provided an effective way to terminate stranded and solid lead wire in the telecommunications industry. Increasing demand for cost reductions in the highly competitive FHP market eventually drove the transfer of IDC technology into these and other magnet wire applications. To meet this demand, TE developed the MAG-MATE IDC interconnection system, which comprises efficient and durable termination products for medium- and high-volume manufacturing operations. In total the MAG-MATE product portfolio covers a wide range of wire gauges and offers a multitude of possible terminal contact geometries. For applications with space constraints, slim-line and mini solutions offer an efficient termination option.

How MAG-MATE IDC technology works

In the IDC-based interconnection system, box-shaped dual-beam terminals reside on a continuous strip. The manufacturer inserts the terminals into a plastic cavity using either semi or fully automatic insertion equipment. The plastic cavity can be moulded onto the customer’s existing bobbin or can be part of a separately attached housing.

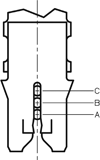

This moulded cavity has two slots at opposing sides with a chamfered lead-in at the top of each slot. The magnet wire from the bobbin is pre-positioned into these two slots either manually or by the winding equipment. The wire is supported inside the cavity by means of an integral wire support or ‘anvil’ feature.

The MAG-MATE metal terminal has two IDC slots with chamfered lead-ins at the slot entrances. The terminal is positioned over the magnet wire in the housing cavity and inserted. Specially designed terminal features, called ‘nickers’, clean the insulation film from the wire surface during insertion. Once the terminal is fully seated, the wire is captured within the two insulation displacement slots to provide a reliable termination (Figure 2).

The wire deforms to an oblong shape. During this process four gas-tight points of contact (two on each beam) are created between the wire and terminal. The opposing side walls of each terminal slot have residual spring energy that maintains constant pressure on the wire, providing a reliable, long-term connection. Similarly, the moulded plastic slots grip the wire on each side of the metal terminal, providing strain relief.

Terminating aluminium magnet wire

The termination of aluminium magnet wire has presented unique challenges for IDC technology. Environmental and mechanical stresses will cause aluminium to experience creep and stress relaxation to a much higher degree than copper.

Magnet wire manufacturers have been able to minimise the creep and stress relaxation characteristics by alloying aluminium magnet wire with iron, but at a higher cost than traditional aluminium wire. Instead, the MAG-MATE IDC termination can be designed to compensate for the material properties of aluminium without impacting the aluminium alloy price, the wire weight or the termination quality.

Therefore TE conducted studies to verify the factors that result in long-term successful IDC termination of aluminium magnet wire. These studies incorporated environmental and mechanical stresses and evaluated the effects of wire position within the IDC slot, IDC slot compliance, terminal plating materials and strain relief features.

The tests showed a very stable performance of MAG-MATE terminals on aluminium magnet wire as long as manufacturers take certain precautions during the termination process. Namely, to ensure a successful termination on aluminium wire, the manufacturer must not over-insert the wire into the IDC slots and must incorporate strain relief features in the plastic housing.

Details on the influence of the wire end position

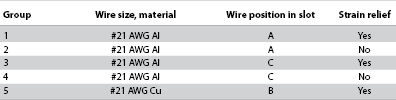

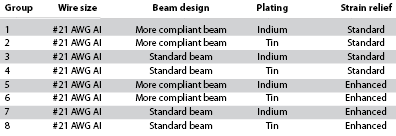

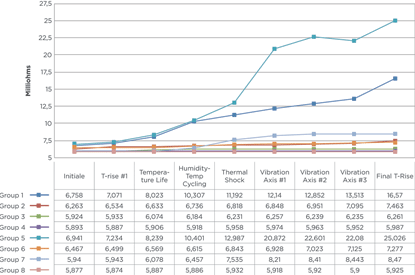

Table 1 and Figure 3 both illustrate different test samples, grouped according to the depth of wire insertion (ranging from A to C), and the presence or absence of a strain relief feature. Wire end position A is the most compliant, providing maximum spring-back capability and longest termination life on aluminium magnet wire. Wire end position B is the standard wire insertion depth used with copper, which results in normal spring-back capabilities and termination life.

Wire end position C proved to be the least compliant, providing virtually no spring-back and leading to a short termination life on aluminium magnet wire. Test data for groups 3 and 4 shown in Table 1 illustrate that over-insertion of the magnet wire into the IDC slot compromises the successful termination of aluminium magnet wire.

The absence of a strain relief feature (Group 4) significantly increases the instability of the termination. As a result, TE now specifies an optimal insertion depth for the terminal, measured from the top of the plastic cavity to the top of the terminal. This assures proper aluminium wire placement and eliminates the need for destructive inspection.

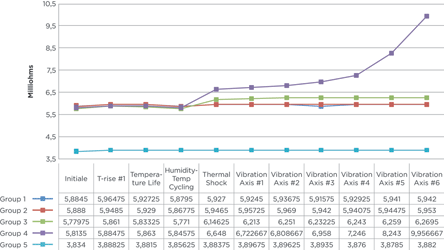

Figure 3 compares the average resistance levels of the MAG-MATE terminal on aluminium wire and subjected to environmental and mechanical stresses. Some samples provided strain relief by means of an interference fit between the magnet wire and plastic cavity slots. Other samples did not incorporate the strain relief feature. One test group included copper magnet wire as a base line for comparison.

Evaluating the possible influence of connector design modifications

Analysis of the influence of the wire end posit-ion revealed just how important the resilience and long-term pre-loading of the IDC slot beams are for mechanical durability. But what about the electric properties of the interconnection? Would changes in the IDC design improve eg, resistance?

Figure 4 shows a similar comparison of average resistance levels of standard and modified MAG-MATE terminals used with aluminium magnet wire. In this case the groups represent different combinations of slot designs, plating materials and strain relief, as indicated in Table 2. Indium plating was selected due to its ability to inhibit aluminium oxides.

Results show that the standard connector design (Group 4) offers the best performance. Special indium plating actually diminished termination performance on aluminium magnet wire. The combination of a more compliant slot with the special plating (Group 1) clearly produced unstable terminations. Additionally, enhanced strain relief offered no improvement over a standard interference fit between the magnet wire and the slot in the plastic cavity.

It can therefore be concluded that the standard MAG-MATE terminal with the wire terminated in the compliant region of the slot and standard strain relief from the plastic cavity offer the best performance for aluminium magnet wire.

Conclusion

These TE studies indicate that FHP motor manufacturers can switch from copper to aluminium magnet wire and use standard insulation displacement terminals to eliminate labour intensive pre-stripping or soldering.

In order to ensure that the termination process leaves the wire in a compliant region of the connector slot, the TE engineering team will specify an optimum insertion depth for an application. In addition to that, a strain relief mechanism is required. However, tests have shown that the interference fit between magnet wire and plastic cavity slot can provide an adequate solution. Finally, TE does not recommend the use of single-beam IDC terminals for aluminium magnet wire terminations because they do not provide the robustness and control needed for such a dynamic conductor as aluminium wire.

For more information contact TE Connectivity, +27 (0)41 503 4500, [email protected], www.te.com

© Technews Publishing (Pty) Ltd | All Rights Reserved