Today, cables have to satisfy numerous requirements to satisfy different tasks, with the end user assuming that the chosen cable will function correctly in every application. However, this is not always the case. Cables are protected in several ways from electrical influences and also partially against mechanical faults. They can therefore have different designs suiting their future application, which, by implication, also extends to the cable insulation. Round wires and braids, for instance, can be insulated with various materials in different geometries.

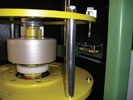

Apart from the outer jacket, individual cores can also be encased in various materials such as Kapton, Teflon, mica, polyester, copper or glass fibre yarn which is wound in tape form around the individual wire or the braid. This kind of insulation is applied by a banding machine where the unsheathed wire is fed into the machine from the one side. Depending on the configuration, there can be one or two banding units. These units consist of a receiver, also called a bobbin, for the banding tape, which is wound on a roll. The bobbin is positioned inside the head, which guides the tape. The wire runs in the centre of this element.

When the wire is moved through the machine, the bobbin and head are constantly rotating in order to band the wire with the inserted tape. Depending on which cable has to be produced, it is possible to let the tape overlap slightly, to change the winding pitch or to vary the tensile force with which the tape is wound. This is possible because the head and bobbin can rotate independently from each other and therefore achieve different tensile forces and angles. If a second banding unit is installed, the wire can be wrapped again and also in the opposite direction to the first wrapping if required.

New sensor solution

In order to optimise the production of the insulation, the tension during the complete banding process has to be controlled, which makes it important to know the current diameter of the bobbin – this diameter decreases during production. Traditional attempts to measure the diameter make use of a reflection light barrier. The sensor unit is attached to a mechanism that constantly pivots to the bobbin. If the existing diameter of the bobbin penetrates this light barrier, a pulse is generated, which can be used as an indication of the diameter.

However, as the mechanism for this solution is complicated, German cable production company Lukas Anlagenbau looked for a new solution. Measurement technology specialist Micro-Epsilon solved this task using its non-contact laser triangulation sensor. The laser sensor is mounted inside the machine next to the drum. It continuously measures the current diameter of the roll from this position. The recorded measurement data is transmitted to a winding processor, which then calculates the desired torque of the bobbin drive.

One of the problems with this application is the fact that different tape materials are being measured – from shiny to transparent. Shiny metals present a problem to many laser sensors due to their direct reflective characteristics. The tapes used have a thickness of around 0,1 mm and are 6 to 8 mm wide. Micro-Epsilon’s solution, the optoNCDT 1401 laser sensor, has a measuring range of 200 mm and competently performs these measurements even on shiny metal and transparent surfaces. The laser spot reflects onto the coil surface and calculates the precise diameter of the coil. For data acquisition, it must be noted that the head has many vertical cross members for the tape guide. These continuously stray across the measuring range of the sensor and must also be suppressed by software so that only the diameter value is provided as a measurement result.

Two systems for different requirements

Depending on the application requirements for the end product, two basic types of sensor systems are available, which ensure that the tape does not unwind unnecessarily in the case of a stoppage or production slowing down and therefore interrupting the production process downstream. Tapes can be inserted in the standard version, which can tolerate tensile loads of more than 4 N. The required tape tension is achieved by braking the bobbin with a torque-controlled drive. The winding processor determines the required torque for the drive from the measurement data obtained by the laser sensor.

The other version has a driven bobbin which is available for more sensitive tapes from a tape tension of 1 N. In this system, the spindle diameter is also measured by the laser sensor, as is the torque. Both measurements are used in the winding processor for calculating the correct torque or tension. External influences such as friction and different storage temperatures have a negligible effect with this more sensitive arrangement. The system can be regulated and controlled precisely and thus yields a high quality end product.

Working closely with Micro-Epsilon, Lukas Anlagenbau, founded in 1959, has created an innovative solution for measuring the diameter of banding spindles. This simple and convenient solution makes complex mechanisms redundant.

For more information contact Dieter Netter, Associated Technology, +27 (0)11 802 3320, [email protected], www.associated-technology.co.za

| Tel: | +27 11 802 7020 |

| Email: | [email protected] |

| www: | |

| Articles: | More information and articles about Associated Technology |

© Technews Publishing (Pty) Ltd | All Rights Reserved