Probing is critical to making quality oscilloscope measurements, and often the probe is the first link in the oscilloscope measurement chain. If probe performance is not adequate for your application, you will see distorted or misleading signals on your oscilloscope.

Selecting the right probe for your application is the first step toward making reliable measurements. How you use the probe also affects your ability to make accurate measurements and obtain useful measurement results. In this article, you will find eight useful hints for selecting the right probe for your application and for making your scope probing better. The following probing tips will help you avoid most common probing pitfalls.

Hint #1: Compensate probe before use

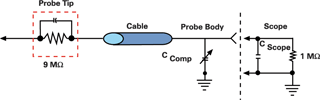

Most probes are designed to match the inputs of specific oscilloscope models. However, there are slight variations from scope to scope and even between different input channels in the same scope. Make sure you check the probe compensation when you first connect a probe to an oscilloscope input because it may have been adjusted previously to match a different input. To deal with this, most passive probes have built-in compensation RC divider networks. Probe compensation is the process of adjusting the RC divider so that the probe maintains its attenuation ratio over the probe's rated bandwidth.

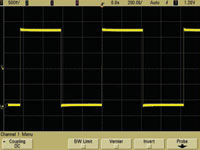

If your scope can automatically compensate for the performance of probes, it makes sense to use that feature. Otherwise, use manual compensation to adjust the probe's variable capacitance. Most scopes have a square wave reference signal available on the front panel to use for compensating the probe. You can attach the probe tip to the probe compensation terminal and connect the probe to an input of the scope. Viewing the square wave reference signal, make the proper adjustments on the probe using a small screw driver so that the square waves on the scope screen look square.

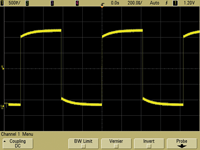

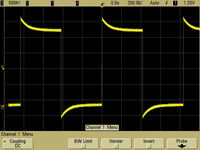

The diagram at the top of Figure 1-2 shows how to properly adjust the compensating capacitor in the termination box at the end of the probe. As you can see in the picture, you can have either overshoot or undershoot on the square wave when the low-frequency adjustment is not properly made. This will result in high-frequency inaccuracies in your measurements. It is very important to make sure this compensation capacitor is correctly adjusted.

Hint #2: Low current measurement tips

In recent years, engineers working on mobile phones and other battery-powered devices have demanded higher-sensitivity current measurement to help them ensure the current consumption of their devices is within acceptable limits. Using a clamp-on current probe with an oscilloscope is an easy way to make current measurement that does not necessitate breaking the circuit. But this process gets tricky as the current levels fall into the low milliampere range or below.

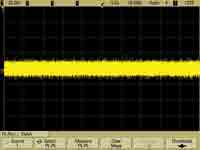

As the current level decreases, the oscilloscope's inherent noise becomes a real issue. All oscilloscopes exhibit one undesirable characteristic - vertical noise.

When you are measuring low-level signals, measurement system noise may degrade your actual signal measurement accuracy.

Since oscilloscopes are broadband measurement instruments, the higher the bandwidth of the oscilloscope, the higher the vertical noise will be. You need to carefully evaluate the oscilloscope's noise characteristics before you make measurements. The baseline noise floor of a typical 500 MHz bandwidth oscilloscope measured at its most sensitive V/div setting is approximately 2 mV peak-to-peak.

In making low-level measurements, it is important to note that the acquisition memory on the oscilloscope can affect the noise floor. On the other hand, a modern AC/DC current probe such as Agilent's N2783A100 MHz probe is capable of measuring 5 mA of AC or DC current with approximately 3% accuracy. The current probe is designed to output 0,1 V per one ampere current input. In other words, the oscilloscope's inherent 2 mVpp noise can be a significant source of error if you are measuring less than 20 mA of current.

So, how do you minimise the oscilloscope's inherent noise? With modern digital oscilloscopes, there are a number of possible approaches:

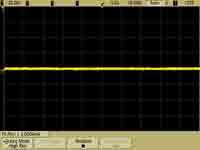

1. Bandwidth limit filter - Most digital oscilloscopes offer bandwidth limit filters that can improve vertical resolution by filtering out unwanted noise from input waveforms and by decreasing the noise bandwidth. Bandwidth limit filters are implemented with either hard-ware or software. Most bandwidth limit filters can be enabled or disabled at your discretion.

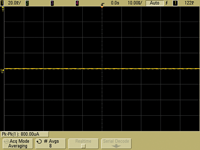

2. High-resolution acquisition mode - Most digital oscilloscopes offer 8 bits of vertical resolution in normal acquisition mode. High-resolution mode on some oscilloscopes offers much higher vertical resolution, typically up to 12-16 bits, which reduces vertical noise and increases vertical resolution. Typically, high-resolution mode has a large effect at slow time/div settings, where the number of on-screen data points captured is large. Since high-resolution mode acquisition averages adjacent data points from one trigger, it reduces the sample rates and bandwidth of the oscilloscope.

3. Averaging mode - When the signal is periodic or DC, you can use averaging mode to reduce the oscilloscope's vertical noise. Averaging mode takes multiple acquisitions of a periodic waveform and creates a running average to reduce random noise. High-resolution mode does reduce the sample rates and bandwidth of the signal, whereas normal averaging does not. However, averaging mode compromises the waveform update rate as it takes multiple acquisitions to average out the waveforms and draw a trace on the screen. The noise reduction effect is larger than with any of the methods above as you select a greater number of averages.

Now that you know how to lower the oscilloscope's vertical noise with one of the techniques above, let us take a look at how to improve accuracy and sensitivity of a current probe. There are a number of different types of current probes. The one that offers the most convenience and performance is a clamp-on AC/DC current probe that you can clip onto a current carrying conductor to measure AC and DC current.

Two useful tips for using this type of current probe:

1. Remove magnetism (demagnetise/ degauss) and DC offset - To ensure accurate measurement of low-level current, you need to eliminate residual magnetism by demagnetising the magnetic core. Just as you would remove undesired magnetic field built up within a CRT display to improve picture quality, you can degauss or demagnetise a current probe to remove any residual magnetisation. If a measurement is made while the probe core is magnetised, an offset voltage proportional to the residual magnetism can occur and induce measurement error. It is especially important to demagnetise the magnetic core whenever you connect the probe to power on/off switching or excessive input current. In addition, you can correct a probe's undesired voltage offset or temperature drift using the zero adjustment control on the probe.

2. Improve the probe sensitivity - A current probe measures the magnetic field generated by the current flowing through the jaw of a probe head. Current probes generate voltage output proportional to the input current. If you are measuring DC or low-frequency AC signals of small amplitude, you can increase the measurement sensitivity on the probe by winding several turns of the conductor under test around the probe. The signal is multiplied by the number of turns around the probe. For example, if a conductor is wrapped around the probe five times and the oscilloscope shows a reading of 25 mA, the actual current flow is 25 mA divided by 5, or 5 mA. You can improve the sensitivity of the current probe by a factor of 5 in this case.

| Tel: | +27 12 678 9200 |

| Email: | [email protected] |

| www: | www.concilium.co.za/test-measurement |

| Articles: | More information and articles about Concilium Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved