The design and fabrication of a contact can significantly impact both the electrical and mechanical performance of a system, making it a critical factor to consider when selecting interconnects for high speed applications.

Stamped/cut vs. formed design

While traditional stamped/cut contact designs offer the ability to produce ultra fine pitch connectors, several properties resulting from the design and fabrication process make them undesirable for high speed applications. To address these issues, formed contact designs, such as the one used in Samtec's Edge Rate contacts, are often employed.

Electrical performance

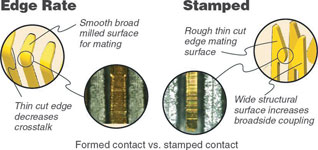

Stamped/cut contacts tend to exhibit more coupling, and therefore more crosstalk. By decreasing the amount of parallel metal surface area in a contact system the capacitive coupling is reduced. While this can be difficult to achieve with stamped contacts, it is easily accomplished with formed contacts.

In these designs, two 'plates' are essentially placed flat in the same plane so that direct coupling only occurs on the much smaller edge of the plates. Samtec's Edge Rate Contacts use a formed design such as this to achieve reduced broadside coupling and crosstalk, resulting in excellent signal integrity.

Impedance and return loss are also negatively affected by stamped/cut contact design due to the number of geometry changes, while the formed contact geometry is optimised for superior impedance matching.

Mechanical performance

The mechanical performance of an interconnect system can also be negatively affected by stamped/cut designs. These contacts mate on the cut edge of the stamping, a rough surface which can create 'wear tracks' on the contact beams. These wear tracks decrease the durability (or cycle life) of the connector.

The milled surface of a formed edge rate contact, however, creates a smooth mating surface which reduces the wear on the contact, increasing the durability and cycle life of the system. In addition, a stamped/cut contact is considerably thicker than it is wide, creating a high spring rate. Since edge rate contacts are wider than they are thick, the resulting lower spring rate provides for a lower insertion/withdrawal force.

Edge rate solutions

Samtec offers a full line of board-to-board, cable-to-board and I/O solutions, which employ rugged edge rate contacts, making them ideal for applications where durability and signal integrity are critical.

Board level interconnects

Samtec's edge rate interconnect strip system (ERM8/ERF8 Series) provides an increased cycle life over a one-piece system, and robust performance when zippered during unmating. This 0,8 mm pitch system offers estimated performance to 7 GHz in both DP and SE configurations.

The RiseUp Edge Card Stacking system (RU8 Series) employs a high speed board with embedded ground plane and mates with micro edge card connectors. It is available with single-ended or differential pair routing, and with optional board locks for increased durability in rugged applications.

The SEARAY Open Pin Field Array (SEAM/SEAF Series) is ideal for maximum grounding and routing flexibility, and offers up to 500 single-ended I/Os or 125 differential pairs. DP array differential pair array (DPAM/DPAF Series) features a staggered pin layout, perimeter grounds, and up to 168 usable pairs.

Cable systems

The 0,8 mm pitch, 50 Ω micro coax edge rate cable system (ERCDA Series) is designed for mating with the board level edge rate socket. It features direct soldering of the coax cable to the contacts with no PCB required.

Samtec's 100 Ω Twinax edge card cable system (EEDP Series) mates with vertical and right angle edge rate connectors (HSEC8 Series) and is available with a choice of ruggedising options, including a positive latching system.

The 100 Ω Twinax data bank high speed/high density cable system (GCCA/GCAM Series) optimises signal integrity with a patent-pending design that does not require a transition board between the cable and contacts. It is currently available with 32 or 64 pairs, with additional configurations in design.

High speed I/O

The 100 Ω differential pair edge rate I/O cable system (EPLSP Series) uses a 26 AWG MiniSkew low skew pair cable, which is shielded for EMI protection, and offers estimated performance of up to 2,5 GHz. The cable plug features rugged edge rate contacts, a die cast housing and positive latching system.

For more information contact Samtec, +27 (0)11 454 4317, [email protected], www.samtec.com

© Technews Publishing (Pty) Ltd | All Rights Reserved