To a large extent, the reliability and longevity of a battery hinges on the quality of the charger. In a price-competitive market, chargers are often given low priority, especially for consumer products. In this article, we assess the charger as the quintessential provider and guardian of the battery. We look at recommended charge methods to increase the performance of NiCd, NiMH and Li-ion packs.

A battery should always remain cool during charging because high temperatures shorten battery life. However, some temperature rise cannot be avoided when charging nickel-based batteries. The temperature peaks when the battery approaches full charge, then moderates after the battery switches to trickle charge. The battery should eventually cool to room temperature.

If the temperature remains above room temperature after a few hours in ready mode, the charger is performing incorrectly. Remove the battery when ready because any prolonged trickle charging will damage the battery. The caution applies especially to NiMH because this chemistry cannot absorb overcharge well. A lithium-based battery should never get warm during charge. If this happens, either the battery or the charger is faulty. Discontinue its use.

Nickel-based chargers are grouped into three categories:

* Slow charger - the slow charger, also known as 'overnight charger', applies a fixed charge of about 0,1C* (one tenth of the rated capacity) for as long as the battery is connected. [The C-rate is a unit by which charge and discharge currents are scaled. A charge current of 1000 mAh (1C) will charge a 1000 mAh battery in slightly more than one hour.] Charge time is 14 to 16 hours. Slow chargers are found in cordless phones, portable CD players and similar consumer goods.

* Quick charger - the quick-charger, or rapid charger, serves in the middle of the range, both in terms of charging time and price. Charging takes three to six hours and the battery switches to trickle charge when ready. Quick-chargers accommodate nickel-based or lithium-based batteries and service commercial products such as cellphones, laptops and camcorders.

* Fast charger - this charger offers several advantages; the obvious one is shorter charge times. At a 1C charge rate, an empty NiCd or NiMH typically charges in a little more than an hour. Accurate full-charge detection is important. Once fully charged, the charger switches to topping and then trickle charge. Fast chargers are used for industrial equipment such as two-way radios, medical devices and power tools.

Simple guidelines:

* A charger for NiMH can also accommodate NiCd, but not the other way around. A charger especially designed for NiCd would overcharge the NiMH battery.

* Nickel-based batteries prefer fast charge because it reduces crystalline formation (memory).

* Nickel and lithium-based batteries require different charge algorithms. The two chemistries can normally not be interchanged in the same charger.

* If not used regularly, remove the battery from the charger and apply a topping-charge before use. Do not leave the battery in the charger for standby.

Charging nickel cadmium

Battery manufacturers recommend to slow charge a new NiCd for 24 hours before use. This process brings the cells within a battery pack to equal charge level because each cell self-discharges at a different rate. The initial trickle charge also redistributes the electrolyte to remedy dry spots on the separator brought on by gravitation of the electrolyte during long storage.

Some battery manufacturers do not fully form the cells before shipment. Full performance is reached after the battery has been primed through several charge/discharge cycles, either with a battery analyser or through normal use. In some cases, 50 to 100 discharge/charge cycles are needed to fully form a nickel-based battery. Quality cells, such as those made by Sanyo and Panasonic, perform to specification after five to seven cycles. The initial readings may be inconsistent but the capacity becomes steady once fully primed. A slight capacity peak is observed between 100 and 300 cycles.

Most rechargeable cells are equipped with a safety vent to release excess pressure if over-charged. The safety vent on a NiCd cell opens between 150 and 200 psi. (The pressure of a car tyre is about 35 psi.) With a resealable vent, no damage occurs on venting but some electrolyte is lost and the seal may leak afterwards. A white powder accumulating at the vent opening indicates venting activities.

Commercial chargers are often not designed in the best interests of the battery. This is especially true with chargers that measure the battery's charge state solely through temperature sensing. Although simple and inexpensive, charge termination by absolute temperature is not accurate.

More advanced NiCd chargers sense the rate of temperature increase. Defined as dT/dt (delta temperature/delta time), this charge detection system is kinder on the batteries than a fixed temperature cut-off, but the cells still need to generate some heat to trigger detection.

More precise full charge detection can be achieved with the use of a microcontroller that monitors the battery voltage and terminates the charge when a certain voltage signature occurs. A drop in voltage signifies full state-of-charge. Known as negative delta V (NDV), this phenomenon is most pronounced on NiCd charging at 0,5C and higher. Chargers based on NDV must also observe battery temperature because ageing cells and cell mismatch reduce the voltage delta.

Fast charging improves charge efficiency. At 1C, the efficiency is 1,1 or 91% and the charge time of an empty pack is slightly longer than one hour. On a 0,1C charge, the efficiency drops to 1,4 or 71% and the charge time is about 14 hours. On a partially-charged battery or one that cannot hold full capacity, the charge time is shorter accordingly.

In the initial 70% of charge, the charge acceptance of a NiCd battery is close to 100%. Almost all energy is absorbed and the battery remains cool. Currents of several times the C-rating can be applied without causing heat build-up. Ultra-fast chargers use this phenomenon to charge a battery to the 70% level within minutes. The charge continues at a lower rate until fully charged.

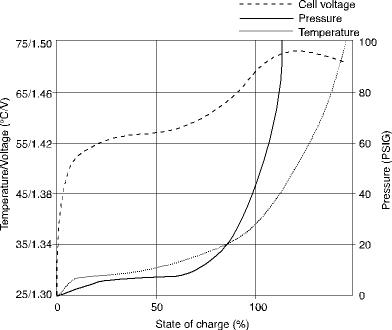

Past 70%, the battery gradually loses the ability to accept charge. The pressure rises and the temperature increases. In an attempt to gain a few extra capacity points, some chargers allow a short period of overcharge. Figure 1 illustrates the relationship of cell voltage, pressure and temperature while a NiCd is being charged.

Ultra-high capacity NiCd batteries tend to heat up more than standard NiCd if charged at 1C or higher. This is partly due to increased internal cell resistance. To moderate temperature buildup and still maintain short charge times, advanced chargers apply a high current at the beginning and then lower the amount to harmonise with the charge acceptance.

Interspersing discharge pulses between charge pulses improves the charge acceptance of nickel-based batteries. Commonly-referred to as burp or reverse-load charging, this method promotes high surface area on the electrodes to improve the recombination of the gases generated during charge. The results are better performance, reduced memory and longer service life.

After the initial fast charge, some chargers apply a timed topping charge, followed by trickle charge. The recommended trickle charge for NiCd is between 0,05C and 0,1C. Because of memory concerns and compatibility issues with NiMH, modern chargers tend to use lower trickle charge currents.

Charging nickel-metal hydride

Chargers for NiMH batteries are similar to NiCd systems but require more complex electronics. To begin with, the NiMH produces a very small voltage drop at full charge and the NDV is almost non-existent at charge rates below 0,5C and elevated temperatures. Ageing and degenerating cell match diminish the already minute voltage delta further.

A NiMH charger must respond to a voltage drop of 8 to 16 mV. Making the charger too sensitive may terminate the fast charge halfway through the charge because voltage fluctuations and noise induced by the battery and charger can fool the NDV detection circuit. Most of today's NiMH fast chargers use a combination of NDV, rate-of-temperature-increase (dT/dt), temperature sensing and timeout timers. The charger utilises whatever comes first to terminate the fast-charge.

NiMH batteries that are allowed a brief overcharge deliver higher capacities than those charged by less aggressive methods. The gain is approximately 6% on a good battery. The negative is shorter cycle life. Rather than 350 to 400 service cycles, this pack may be exhausted after 300.

NiMH batteries should be rapid rather than slow charged. Because NiMH does not absorb overcharge well, the trickle charge must be lower than that of NiCd and is set to around 0,05C. This explains why the original NiCd charger cannot be used to charge NiMH batteries.

It is difficult, if not impossible, to slow-charge a NiMH battery. At a C rate of 0,1C and 0,3C, the voltage and temperature profiles fail to exhibit defined characteristics to measure the full charge state accurately and the charger must rely on a timer. Harmful overcharge can occur if a partially or fully-charged battery is charged with a fixed timer. The same occurs if the battery has aged and can only hold 50% instead of 100% charge. Overcharge could occur even though the NiMH battery feels cool to the touch.

Lower-priced chargers may not apply a fully saturated charge. The full-charge detection may occur immediately after a given voltage peak is reached or a temperature threshold is detected. These chargers are commonly promoted on the merit of short charge time and moderate price. Some ultra-fast chargers also fail to deliver full charge.

Charging lithium-ion

Whereas chargers for nickel-based batteries are current limiting devices, Li-ion chargers are voltage limiting. There is only one way to charge lithium-based batteries. The so-called 'miracle chargers', which claim to restore and prolong batteries, do not exist for lithium chemistries. Neither does a super-fast charging solution apply. Manufacturers of Li-ion cells dictate very strict guidelines in charge procedures.

The early graphite system demanded a voltage limit of 4,10 V/cell. Although higher voltages deliver more capacity, cell oxidation shortened the service life if charged above the 4,10 V/cell threshold. This problem has been solved with chemical additives. Today, most Li-ion cells are charged to 4,20 V with a tolerance of ±0,05 V/cell.

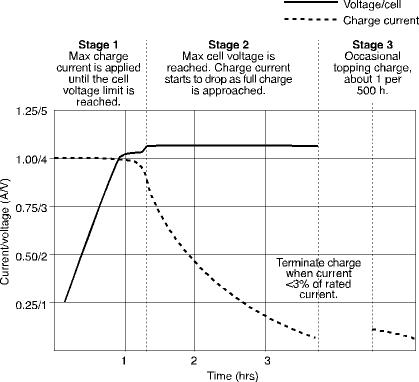

The charge time of most chargers is about three hours. The battery remains cool during charge. Full charge is attained after the voltage has reached the voltage threshold and the current has dropped low and levelled off.

Increasing the charge current does not shorten the charge time by much. Although the voltage peak is reached quicker with higher current, the topping charge will take longer. Figure 2 shows the voltage and current signature of a charger as the Li-ion cell passes through stage one and two.

Some chargers claim to fast-charge a Li-ion battery in one hour or less. Such a charger eliminates stage 2 and goes directly to 'ready' once the voltage threshold is reached at the end of stage 1. The charge level at this point is about 70%. The topping charge typically takes twice as long as the initial charge.

No trickle charge is applied because Li-ion is unable to absorb overcharge. Trickle charge could cause plating of metallic lithium, a condition that renders the cell unstable. Instead, a brief topping charge is applied to compensate for the small self-discharge the battery and its protective circuit consume. Depending on the battery, a topping charge may be repeated once every 20 days. Typically, the charge kicks in when the open terminal voltage drops to 4,05 V/cell and turns off at 4,20 V/cell.

What if a battery is inadvertently overcharged? Li-ion batteries are designed to operate safely within their normal operating voltage but become increasingly unstable if charged to higher voltages. When charging above 4,30 V, the cell causes lithium metal plating on the anode; the cathode material becomes an oxidising agent, loses stability and releases oxygen. Overcharging causes the cell to heat up.

Much attention has been placed on the safety of Li-ion to prevent over-charge and over-discharge. Commercial Li-ion battery packs contain a protection circuit that prevents the cell voltage from going too high while charging. The upper voltage threshold is typically set to 4,30 V/cell. Temperature sensing disconnects the charge if the cell temperature approaches 90°C; and a mechanical pressure switch on many cells permanently interrupt the current path if a safe pressure threshold is exceeded. Exceptions are made on some spinel (manganese) packs containing one or two small cells. The charge process of a Li-ion Polymer is similar to Li-ion. These batteries use a gelled electrolyte to improve conductivity.

Charging at high and low temperatures

Rechargeable batteries work under a reasonably wide temperature range. This, however, does not automatically permit charging at these extreme conditions. While hot or cold temperatures cannot always be avoided, recharging a battery is at the control of the user. Efforts should be made to charge at room temperatures. No commercial battery should be charged below freezing.

Nickel-based batteries should only be fast-charged between 10°C to 30°C. Below 5°C, the ability to recombine oxygen and hydrogen is greatly reduced and the resulting pressure build up may cause the cells to vent. The charge acceptance of nickel-based batteries at higher temperatures is drastically reduced. A battery that provides a capacity of 100% if charged at moderate room temperature only accepts 70% if charged at 45°C. This explains the poor performance of vehicular chargers in the summer.

The Li-ion batteries offer reasonably good charge performance throughout the temperature range. Below 5°C, the charge should be with less than 1C. Charging at freezing temperatures must be avoided because plating of lithium metal could occur.

The Cadex universal conditioning chargers (UCC) feature a built-in temperature sensor that applies a trickle charge if the battery is too cold. No charge is applied if too hot. These advanced chargers use reverse load charge and detect the full charge by NDV, dT/dt sensing and timers.

Summary

Commercial fast-chargers are often not designed in the best interests of the battery. The two common battery killers are high temperature during charge and incorrect trickle charge after charge. Choosing a quality charger makes common sense. This is especially true when considering the high cost of battery replacements and the frustration poorly performing batteries create. In most cases, the extra money invested in a more advanced charger is returned in longer lasting and better performing batteries.

| Tel: | +27 11 466 1156 |

| Email: | [email protected] |

| www: | www.uniross.co.za |

| Articles: | More information and articles about Uniross Batteries |

© Technews Publishing (Pty) Ltd | All Rights Reserved