Until recently, applications for high current rate capabilities were reserved for nickel-cadmium and nickel-metal-hydride batteries. These applications include power tools and medical equipment. Much has changed in the fields of lithium-based batteries during the last few years and high current lithium-ion now claim similar or higher load capabilities to nickel-based systems.

These new-technology batteries are expected to have a similar impact on high-power portable products as the introduction of lithium-ion had on the consumer electronics market in the 1990s.

Most lithium-ion batteries used for portable applications are cobalt-based. High production volume enables the battery to be manufactured at a relatively low cost. They consist of a cobalt oxide positive electrode (cathode) and a graphic carbon in the negative electrode (anode). One of the main advantages of the cobalt-based battery is its high energy density. That makes this chemistry attractive for cellphones, laptops and cameras.

In spite of its great popularity, the cobalt-based lithium-ion has some limitations: It is not very robust and cannot take a high charge and discharge currents. Trying to force a rapid charge or loading the battery with excess discharge current would overheat the pack and its safety would be jeopardised. The safety circuit of the cobalt-based battery is typically limited to a charge and discharge rate of about 1C. This means that a 2400 mAh 18650 cell can only be charged and discharged with a maximum current of 2,4 A. Another drawback of the cobalt system is the increase of the internal resistance that occurs with cycling and ageing. After 2-3 years of use, the pack often becomes unserviceable due to a high voltage drop under load that is caused by elevated internal resistance. This condition cannot be reversed.

New cathode material opened the door for higher rate capability. Moving away from cobalt also helped in lowering manufacturing costs. In 1996, scientists succeeded in using lithium manganese oxide as a cathode material. This substance forms a three-dimensional spinel structure that provides improved ion flow on the electrode. High ion flow reflects in a lower internal resistance and hence higher loading capability. Unlike the cobalt-based lithium-ion, the resistance stays low with cycling and ageing. The battery does age, however, and the overall service life is similar to that of the cobalt system. A further advantage of spinel is its inherent high stability. Spinel needs less in terms of safety circuitry compared to the cobalt system.

Low internal cell resistance is key to high rate capability. This characteristic benefits both in fast-charging and high-current discharging. A spinel-based lithium-ion in an 18650 package can, for example, be discharged at currents of 20-30 A with marginal heat buildup. One-second load pulses of twice the specified current are permissible. At continuous high load requirements, a heat build-up will occur and a cell temperature cannot exceed 80°C. Beside power tools and medical instruments, the spinel-based lithium-ion is a candidate for hybrid cars. Manufacturing cost will need to be lowered and the service life prolonged before this battery system can be used for automotive propulsion applications.

The spinel battery has some disadvantages, however. One of the largest drawbacks is the lower capacity compared to the cobalt-based system. Spinel provides roughly 1200 mAh in an 18650 package, about half that of the cobalt equivalent. In spite of this, spinel provides an energy density that is about 50% higher than that of a nickel-based equivalent.

Types of lithium-ion batteries

Lithium-ion has not yet reached full maturity and the technology is continually improving. The anode in today's cells is made up of a graphite mixture and the cathode is a combination of lithium and other choice metals. It should be noted that all materials in a battery have a theoretical energy density. With lithium-ion, the anode is well optimised and little improvements can be gained in terms of design changes. The cathode, however, shows promise for further enhancements. Battery research is therefore focusing on the cathode material. Another part that has potential is the electrolyte. The electrolyte serves as a reaction medium between the anode and the cathode.

The battery industry is making incremental capacity gains of 8-10% per year. This trend is expected to continue. This, however, is a far cry from Moore's Law that specifies a doubling of transistors on a chip every 18 to 24 months. Translating this increase to a battery would mean a doubling of capacity every two years. Instead of two years, lithium-ion has doubled its energy capacity in 10 years.

Today's lithium-ion comes in many ′flavours′ and the differences in the composition are mostly related to the cathode material. Table 1 summarises the most commonly used lithium-ion on the market today. For simplicity, we summarise the chemistries into four groupings, which are cobalt, manganese, NCM and phosphate.

The cobalt-based lithium-ion appeared first in 1991, introduced by Sony. This battery chemistry gained quick acceptance because of its high energy density. Possibly due to lower energy density, spinel-based lithium-ion had a slower start. When introduced in 1996, the world demanded longer runtime above anything else. With the need for high current rate on many portable devices, spinel has now moved to the frontline and is in hot demand. The requirements are so great that manufacturers producing these batteries are unable to meet the demand. This is one of the reasons why so little advertising is done to promote this product. E-One Moli Energy (Canada) is a leading manufacturer of the spinel lithium-ion in cylindrical form. It is specialising in the 18650 and 26700 cell formats. Other major players of spinel-based lithium-ion are Sanyo, Panasonic and Sony.

Sony is focusing on the nickel-cobalt manganese (NCM) version. The cathode incorporates cobalt, nickel and manganese in the crystal structure that forms a multimetal oxide material to which lithium is added. The manufacturer offers a range of different products within this battery family, catering to users that either need high energy density or high load capability. It should be noted that these two attributes could not be combined in one and the same package; there is a compromise between the two. Note that the NCM charges to 4,10 V/cell, 100 mV lower than cobalt and spinel. Charging this battery chemistry to 4,20 V/cell would provide higher capacities but the cycle life would be cut short. Instead of the customary 800 cycles achieved in a laboratory environment, the cycle count would be reduced to about 300.

The newest addition to the lithium-ion family is the A123 System in which nano-phosphate materials are added in the cathode. Although the manufacturer has not officially announced what metal is being used, it is widely believed to be iron. It claims to have the highest energy density of a commercially available lithium-ion battery. The cell can be continuously discharged to 100% depth-of-discharge at 35C and endures discharge pulses as high as 100C. The phosphate-based system has a nominal voltage of about 3,25 V/cell. The charge limit is 3,60 V. This is far lower than the customary 4,20 V/cell of the cobalt-based lithium-ion. Because of these lower voltages, the A123 System will need to be charged with a special charger. Due to the anticipated strong demand, this cell is expected to be in short supply.

Confusion with voltages

For the last 10 years or so, the nominal voltage of lithium-ion was known to be 3,60 V/cell. This was a rather handy figure because it made up for three nickel-based batteries (1,2 V/cell) connected in series. Using the higher cell voltages for lithium-ion reflects in better watt/hours readings on paper and poses a marketing advantage, however, the equipment manufacturer will continue assuming the cell to be 3,60 V.

The nominal voltage of a lithium-ion battery is calculated by taking a fully charged battery of about 4,20 V, fully discharging it to about 3,00 V at a rate of 0,5C while measuring the average voltage. Because of the lower internal resistance, the average voltage of a spinel system will be higher than that of the cobalt-based equivalent. Pure spinel has the lowest internal resistance and the nominal cell voltage is 3,80 V. The exception again is the phosphate-based lithium-ion. This system deviates the furthest from the conventional lithium-ion system.

Prolonged battery life through moderation

Batteries live longer if treated in a gentle manner. High charge voltages, excessive charge rate and extreme load conditions will have a negative effect and shorten the battery life. This also applies to high current rate lithium-ion batteries. The longevity is often a direct result of the environmental stresses applied. The following guidelines suggest how to prolong battery life.

* The time at which the battery stays at 4,20 V/cell should be as short as possible. Prolonged high voltage promotes corrosion, especially at elevated temperatures. Spinel is less sensitive to high voltage.

* 3,92 V/cell is the best upper voltage threshold for cobalt-based lithium-ion. Charging batteries to this voltage level has been shown to double cycle life. Lithium-ion systems for defence applications make use of the lower voltage threshold. The negative is reduced capacity.

* The charge current of Li-ion should be moderate (0,5C for cobalt-based lithium-ion). The lower charge current reduces the time in which the cell resides at 4,20 V. It should be noted that a 0,5C charge only adds marginally to the charge time over 1C because the topping charge will be shorter. A high current charge tends to push the voltage up and forces it into the voltage limit prematurely.

* A depth of discharge to 80% or less poses less strain on the battery than a full 100% discharge. It is better to charge lithium-ion more often than letting it down too deeply. One does not need to worry about memory as was the case with nickel-cadmium.

Note: In respect to fast-charging and topping charge, the charge behaviour of lithium-ion is similar to lead acid. Here, the voltage threshold of 2,35 V/cell during regular charge needs to be lowered to 2,27 V/cell when the VRLA is on standby. Keeping the voltage at the high threshold would contribute to corrosion. A similar effect occurs with lithium-ion. Not only does a lithium-ion battery live longer with a slower charge rate, high discharge rates also contribute the extra wear and tear.

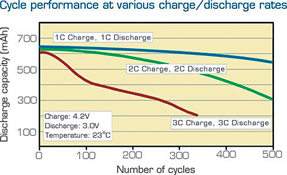

Figure 1 shows the cycle life as a function of charge and discharge rates. Observe the good laboratory performance if the battery is charged and discharged at 1C. (A 0,5C charge and discharge would further improve this rating.)

Battery experts agree that the longevity of lithium-ion is shortened by other factors than charge and discharge rates alone. Elevated temperature while the battery is fully charged is one such element that shortens service life. Even though incremental improvements can be achieved with careful use of the battery, our environment and the services required, are not always conducive to achieve optimal battery life. In this respect, the battery behaves much like us humans - we cannot always live a life that is favourable of achieving a maximum life span.

| Tel: | +27 11 466 1156 |

| Email: | [email protected] |

| www: | www.uniross.co.za |

| Articles: | More information and articles about Uniross Batteries |

© Technews Publishing (Pty) Ltd | All Rights Reserved