In railroad technology, there is a growing demand for modularity and consequently for pluggable systems, for example, for transferring power from one vehicle to another as well as for drive systems within the vehicles.

More and more, these vehicles are constructed modularly in order to make it possible to manufacture and test individual subassemblies separately and then to be able to exchange these quickly and simply for maintenance or upgrading and modernisation purposes. As a result, more and more electrotechnical interfaces for these subassemblies and modules are being given pluggable designs.

A modern connector must consequently meet requirements such as reliable contact transfer and power transmission during a long life in harsh environments, with the most compact and lightweight construction possible and with a high level of operator comfort.

The general idea behind such a high-current connector inevitably includes a certain number of solid contacts that are enclosed in a robust aluminium housing. These solutions are well known and useful, and consequently are used successfully in vehicles. Due to the protective housing of these components, however, the design continually reaches limits with regard to the contacts that can be implemented.

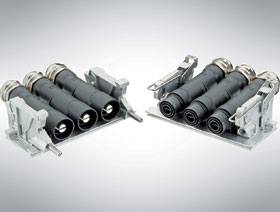

Harting now offers the new Han HC Individual series to extend the possible arrangements of high-current interfaces substantially. The central idea is based on high-current insulator inserts that are locked separately into a universal aluminium rail. Each contact pair is sealed individually and, when combined with the connection-side threaded joint, offers IP66/67 protection in accordance with IEC 60 529. Up to six contacts can be strung together individually and without special tools in a very simple and quick process.

The connector meets DIN 61373 Category 2 requirements for high stress levels due to environmental influences and shock and vibration, allowing attachment to the bogie. The locking also has a modular design, which means that users can choose the number of locking elements depending on application requirements. These are made out of light aluminium and are screwed together to the aluminium rail.

One of the locking’s special highlights is the integrated and exchangeable stainless steel guide bolts that protect the insulator insert from damage while conveniently supporting the insertion process during handling with large cable cross-sections. Because the lever system pushes the connector halves apart during opening, the activation and separation forces in this family are especially small, with forces less than 50 N.

Besides extending the contact arrangement along the fixing rail, the connectors also allow layers to be placed one on top of the other. The result is a power interface with a large number of pins in a compact space. This stacking does not require any additional components, because the locators of the locking elements can be rotated by 180° to connect two levels to each other. The use of materials such as aluminium and plastic makes the product light, but does not hinder their outdoors suitability.

If an installation, such as on a vehicle floor, makes additional protection necessary, an aluminium plate can optionally be added to protect the insulator insert from impact and flying stones. The plastic elements are tested for resistance to environmental influences such as ozone, hydraulic oil, and acidic and base materials. They furthermore exhibit good flame protection levels, such as F2/I3 in accordance with NFF 16 101/102.

For more information contact Harting South Africa, +27 (0)11 575 0017, [email protected], www.harting.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved