Often when doing my rounds visiting customers I am asked to recommend a PCB laminate for a particular design or application. Most often it would seem that the most important consideration for customers (buyers) is price, however when you manage to get past the buyer’s office and actually sit down with the engineer then the more relevant questions get asked, such as: What is the Dk (dielectric constant)? How dimensionally stable is the laminate? How well does it work at high frequencies?

This article attempts to answer these and some of the more common questions asked of us at TraX, and also deals with some of the materials that we have working experience with.

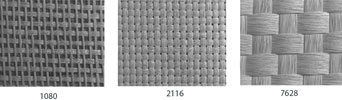

Laminates are manufactured by curing under temperature and pressure layers of cloth or paper with thermoset resins. Varying cloth weaves, cloth thicknesses and resin percentages are used to achieve the desired final thickness and dielectric characteristics.

The cloth or fibre material used and the resin system (a closely guarded secret by most laminate manufacturers) ultimately determine the type designation (FR-4, CEM-1, PTFE, etc.) and the characteristics of the laminate being produced.

It is these characteristics of the different laminates which should guide us in choosing the correct one. Some of the important characteristics to consider are the level to which the laminate is fire retardant, the dielectric constant, the loss factor, thermal conductivity, the glass transition temperature (Tg), and the coefficient of thermal expansion (CTE) which ultimately determines Z-axis expansion or, in layman’s terms, how the thickness of the PCB will change with temperature.

There are numerous laminates on the market today, and it is a fairly rapidly changing environment, as the market seeks out materials with better electrical performances. Covering them all is beyond the scope of this article, however it will cover some of the better known laminates (dielectrics).

There are quite a few different dielectrics that can be chosen to provide different insulating values depending on the requirements of the circuit. Some of these dielectrics are polytetrafluoroethylene (Teflon or PTFE), FR-4, FR-1, CEM-1 or CEM-3.

These dielectrics are generally made up from well-known pre-preg materials used in the PCB industry such as FR-2 (Phenolic cotton paper), FR-3 (cotton paper and epoxy), FR-4 (woven glass and epoxy), FR-5 (woven glass and epoxy), FR-6 (matte glass and polyester), G-10 (woven glass and epoxy), CEM-1 (cotton paper and epoxy), CEM-2 (cotton paper and epoxy), CEM-3 (non-woven glass and epoxy), CEM-4 (woven glass and epoxy) and CEM-5 (woven glass and polyester).

Thermal expansion is an important consideration especially with ball grid arrays and wire bonding technologies, and glass fibre offers the best dimensional stability. Figure 1 shows the different types of glass cloth weaves used in typical FR-4 pre-pregs.

Understanding common laminate types

FR-4 is by far the most common material used today, and about 80% of the PCBs manufactured at TraX are manufactured with this laminate. FR-4 laminates have a well proven track record, they are relatively low cost compared to more exotic materials and their performance is well understood. FR-4 laminates that have copper foils bonded to them are also generally referred to as ‘copper-clad laminates’.

FR-4 laminates are further differentiated by their Tg or glass transition temperature. This is an important standard value for the base material that determines the temperature at which the resin matrix converts from a glassy, brittle condition into a soft, elastic one. The Tg for standard FR-4 is 130°C, whilst high-Tg materials are generally referred to as materials where the Tg is over 170°C.

What does this mean? Well simply put a PCB manufactured on mid-Tg material of 150°C such as what is standard at TraX, will only be able to handle a temperature of 150°C for a very short time. Prolonged exposure to temperatures near to 150°C or above will result in the resin matrix decomposing and subsequent delamination will occur.

A good guideline for continuous thermal load of a PCB is an operating temperature approximately 25°C below the Tg of the laminate used to make the PCB i.e. 125°C in the case of TraX’s standard base material.

The benefits of high-Tg material are:

* High glass flow temperature value (Tg)

* High temperature durability

* Long delamination durability

* Low Z-axis expansion (CTE)

FR2 is a Phenolic paper reinforced laminate which is much cheaper but not as strong or stable as FR-4. It is widely used in cost conscious applications i.e. consumer goods, where the cost of the bare PCB becomes critical.

PTFE is used in high-frequency applications. The laminate has a much lower dielectric constant than FR-4 but is very expensive. Some of the laminates in this group are nearly pure PTFE, whilst some use ceramic fillers to make them more forgiving during fabrication by making them more thermally stable.

PTFE laminates are very challenging from a PCB fabrication perspective, and sodium etchants are required to etch the drilled holes before through-hole plating. TraX has had good success working with PTFE-based laminates.

CEM are probably best classed as modern mixed up laminates, as these can be made in a number of different ways. Some have reinforced outer layers (which make a first class scoring laminate) while others are made from chopped fibres instead of the layers of solid matting. CEM is normally not translucent like FR4 and can even be coloured. TraX is able to process these materials, however they have not proven very popular in the South African market.

Flexible laminates are available in many variants, the most popular of which are the polyimide-based ones. Flexible circuits require different processing lines and equipment to rigid circuit boards and currently TraX only offers this capability from its offshore partners.

Metal core laminates, as the name suggests, are produced by bonding a copper foil to a metal core or base with a dielectric layer between them. There are many dielectric layers available today, from PTFE to polymers with an extremely high thermal conductivity. These substrates are predominantly used for high-power LED applications where good thermal management is required to maintain the efficiency and extend the lifespan of the LEDs.

The metal core used is normally an aluminium alloy, however copper is also used. TraX has an excellent track record working with these metal core substrates and is able to successfully rout and drill metal core laminates as thick as 3,2 mm.

While most FR-4 laminates have a thermal conductivity of about 0,25 W/m/K, TraX’s standard aluminium metal core substrate has a thermal conductivity of 1,0 W/m/K and on some of the more expensive aluminium laminates up to 2,0 W/m/K.

Choosing the right laminate

So now that we know the main types of PCB laminates available, what other considerations are there when choosing a laminate and when should you use FR-4 and when should you use high-frequency laminates?

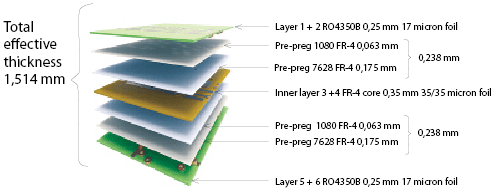

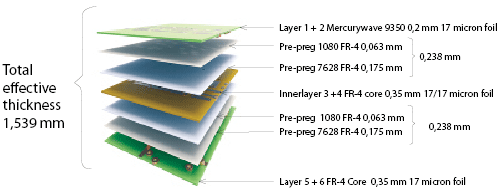

At TraX we have noticed an increasing trend towards hybrid multilayer PCBs, where more features are being incorporated into the PCB design. It is common to have some layers of the PCB with critical electrical demands, while many other layers of the PCB are not.

We have seen customers designing multilayer boards where they have combined high-frequency laminates like Rogers 4003C or Mercurywave 9350 with multiple layers of FR-4 laminates and pre-preg. Usually the main driving force behind this is cost.

The high-frequency laminates are more expensive than FR-4 and typically the critical electrical layers are only required on one or two layers of the PCB so these get routed on the high-frequency laminates, whilst all the other non-critical layers get routed on the FR-4.

Generally speaking, doing this does not complicate the manufacturing process too much, unless of course if PTFE laminates are used, requiring special sodium etching. An important factor to consider when designing hybrid stackups is that you are mixing laminates with different coefficients of thermal expansion and if the stackup is not balanced properly you increase the risk of the PCBs being warped.

Besides reducing cost, there are instances where there is also a reliability benefit that can be achieved from some hybrid builds. The nearly pure PTFE substrates offer excellent electrical performance, however due to high CTE values a high layer count PCB may not be reliable. This is due to the Z-axis expansion which in a multilayer PTFE board could result in barrel cracking of the through-hole vias and even pad lift.

So in this instance a hybrid PCB where the critical electrical layers are routed on the PTFE, and the non-critical layers get routed on the FR-4 will reduce the overall CTE of the hybrid board, thereby making the through-hole connections more robust and reliable, especially if the hybrid PCB will be operating at high temperatures.

High-frequency laminates not only offer improved electrical performance but they also have other characteristics that sometimes make them preferred over FR-4.

In some cases the electric losses of the PCB may not be a concern but maintaining the controlled impedance is a critical concern. Most FR-4 materials have a relatively high TcDk (thermal coefficient of dielectric constant), whilst many of the high-frequency laminates are formulated to have a low TcDk.

A low TcDk is desired for consistent electrical performance. What this means is that laminates with a low TcDk will have very little change in Dk value with an increase in temperature. This means that there will be very little change in the circuit’s controlled impedance with an increase in temperature, and therefore a material with a low TcDk will be a good choice where the final PCB will operate in varying thermal environments.

Another consideration would be were humidity is a concern. In this situation a high-frequency laminate would be preferred even though the circuit may not require low electrical loss. This is due to the fact that high-frequency laminates typically have much lower moisture absorption in comparison to FR-4. Some end-use applications are sensitive to humidity and/or the impedance variation due to humidity; this is due to the fact that moisture absorption changes the Dk of the laminate which in turn affects the impedance.

High-frequency laminates also typically offer better thermal conductivity than FR-4. Some of the thermoset hydrocarbon high-frequency laminates such as Rogers 4003C offer thermal conductivity that is two to three times better than that of FR-4, making it a better choice for designers of a PCB where thermal management is a concern.

Another property of high-frequency laminates which can enable improved impedance control is good thickness control. This refers to the control of thickness during the manufacturing process of the laminates. Most high-frequency laminates generally have a thickness tolerance of less than ±7%, whereas FR-4 laminates can be as much as ±15%.

This is another case where the low electrical loss of the high-frequency laminate is not the reason this material should be chosen, when it is another well controlled property of the high-frequency laminate that is actually needed. In this example boards requiring very strict impedance control should not be manufactured on cheaper FR-4 materials to try and reduce cost, but should rather be manufactured on a high-frequency laminate with good thickness control to improve the yield of the PCBs being manufactured.

To address some of the issues mentioned above, TraX now stocks Mercury- wave 9350 laminates and pre-pregs, which is a high-frequency laminate manufactured by Park Electrochemical Corp. in the United States. The advantage of this material is that it processes much like traditional FR-4, whilst still offering excellent low-loss electrical properties and high thermal reliability.

Mercurywave has a Dk of 3,5 and a Df of 0,004 at 10 GHz measured by stripline. It also has a Tg greater than 200°C with a very low coefficient of thermal expansion as well as excellent copper foil peel strength of 1,23 N/mm. Furthermore it does not require any sodium etching of the through holes. More information is available on the TraX website.

| Tel: | +27 21 712 5011 |

| Email: | [email protected] |

| www: | https://www.icape-group.com/our-companies/trax/ |

| Articles: | More information and articles about ICAPE TRAX / ICAPE South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved