Battery materials company Group14 has developed a silicon material that could make charging habits something to laugh about in the future. If you follow battery technology, you may roll your eyes at another headline about a ‘revolutionary’ new formula, and to be fair, Group14 makes some familiar claims. All of them say they have a breakthrough that will help batteries hold twice the amount of energy – an EV with a 300-mile range would have 600.

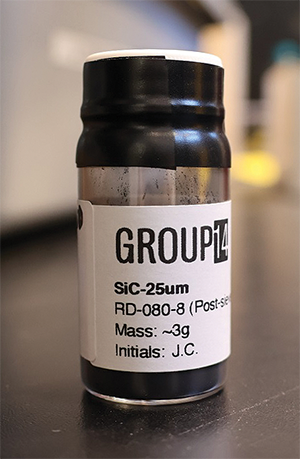

But unlike the others, Group14 appears much further along. At an on-site tour of its Washington state headquarters, PCMag learned that Group14 is already shipping its patented black powder, dubbed SCC55, by the ton to companies that are testing in their products.

“I had a moment during the pandemic when the photos started showing the Himalayas in Delhi, or the Santa Monica mountains in LA, in a way we hadn’t seen in 50-60 years,” says Grant Ray, VP of global market strategy at Group14 and my tour guide. “The way it cleared up with such a profound beauty. That’s what I want to see in 20 years.”

Ray also spoke about his vision for a highly mobile society. Just as previous battery breakthroughs took hefty computers out of ‘the computer room’ and into slim laptop bags, upcoming innovations may allow us to drive around remote areas for days without refuelling.

“The big thing that rechargeable batteries gave us was mobility in our technology we never had before,” he says. “My hope is when we get silicon batteries throughout the world we can live a fully untethered technological life.”

That sounds great, but why hasn’t it happened? An old saying in the battery industry holds a clue: “There are liars, damn liars, and battery suppliers.” In other words, no one can figure it out, and claims that they have are a dime a dozen. So why should we believe Group14?

During my solo tour of Group14 HQ, I had an opportunity to grill Ray for proof that it’s not selling a false bill of goods. “We’re already in the phones of the largest mobile phone maker in China,” he says. “I’ll say millions of phones in China have our materials.” A quick scan of Huawei’s website shows multiple charging-related benefits, and rumours of new products having silicon batteries.

Group14 also made it public that ATL, a large Chinese battery manufacturer that led Group14’s Series A funding round, received its first shipment of SCC55 in early 2023 for use in smartphones. “The Asian markets tend to be more hungry [sic] for new technology,” he says. “There will be a time when US phones have it.”

Speaking from his prior experience working at a Chinese company, Ray attributes the delays to America’s product development processes and layers of bureaucracy that can slow things down.

The same story goes for EVs. US automakers must meet a long list of requirements before they can sell a vehicle. The one holding back Group14’s products from hitting dealers is ‘dual-sourcing’ – all vehicle components must come from at least two plants, so if one shuts down, the product does not have to come off the market.

Those concerns will be abated once two new facilities are completed, one in Moses Lake, Wash., and one in Korea. The latter is a joint venture with battery maker SK, which supplies packs to Ford and to Korea-based Hyundai and Kia.

Ray gave a brief overview of the surprisingly simple manufacturing process. Firstly, they put ‘two commercially available products’ through a reactor to create a carbon solution, which looks a bit like volcanic ash. Secondly, they mill that carbon down to a small molecule, or “the perfect nano spec”. Thirdly, the milled carbon goes through a second reactor to inject silane, a gaseous form of silicon. The molecule now has carbon, silicon, and ‘void space’, or extra room Group14 has engineered into the materials that allow them to expand and contract without bursting out of the battery pack, a problem for silicon batteries in the past.

Finally, the powder goes through quality control, into a bag, and out to a customer. “It’s a wonderfully simple, elegant solution,” Ray says.

The material swaps into existing battery processes, specifically in the anode to replace or complement graphite. Each EV requires several bags of powder, though it depends on whether they blend it with graphite, maybe 10-15%, or create a 100% silicon anode. More silicon means higher price and performance, but Group14 has worked to keep the cost as close to graphite as possible for a one-to-one replacement.

Silicon is a highly abundant element. It comes from “everywhere, not one specific country”, according to Ray, who listed South America, Europe, Asia, and the US as sourcing options.

On top of developing the material, Group14’s equally challenging task has been figuring out how to scale up production to the level large companies require. “We basically locked ourselves in a room for 30 days because nothing was working,” Ray says. “Then one scientist at two in the morning had a eureka moment on what was needed to scale it. The material itself and the machinery we use to make it is the genius.”

Group14 is in testing with “95% of the world’s battery manufacturers”, Ray says, which is required to bring silicon batteries to the masses. When I asked about BYD and Panasonic, he said, “Well how would you get to 95% without them?”

Polestar announced in April 2024 that its ‘silicon-dominant’ battery cells from Storedot, a Group14 partner, charged a Polestar 5 prototype from 10-80% in just 10 minutes.

Volkswagen, Audi, and Porsche are also potential clients, as Volkswagen Group owns all three and Porsche led the Series C funding round with a $400 million contribution. Group14 also purchased a silane gas company in Germany, which gives it “an amazing foothold in Europe to be able to deliver to our partners”.

These companies are negotiating to secure their supply of Group14’s materials for future products. Since multiple OEMs purchase batteries from suppliers like SK and Panasonic, they are working directly with Group14 to ensure those suppliers have enough material for their vehicles.

© Technews Publishing (Pty) Ltd | All Rights Reserved