It seems that everything is going green in today’s environmentally planet-friendly mindset. The concept of energy harvesting has been around for over a decade; however, the implementation of ambient energy-powered systems in the real-world environment has been cumbersome, complex, and costly.

Nevertheless, examples of markets where an energy harvesting approach has been used successfully include transportation infrastructure, wireless medical devices, tyre pressure sensing, and building automation. Specifically, in the case of building automation systems, such things as occupancy sensors, thermostats, and even light switches have eliminated the power or control wiring normally associated with their installation, and have used localised energy harvesting systems instead.

Constructing smart buildings that will conserve energy, encompassing both commercial and residential structures, is a prerequisite to ensure energy efficient structures do not draw heavily from traditional power sources that utilise fossil fuels.

In the case of commercial buildings, making them smart can be critical for the organisation that is housed in them, since having a building that is energy efficient and streamlined helps to reduce energy costs while also providing a productive environment for the workers within them.

However, getting to this point is not without its own set of drawbacks. For example, these buildings will require an infrastructure that can provide the necessary feedback to enable efficient operation of heating and cooling systems, lighting control, and efficient space utilisation. This will most likely necessitate the use of the Internet of Things (IoT) as a methodology to monitor and control the environment and will increase their reliance on alternative power sources to effectively manage and control them.

IoT trends for smart buildings

Smart buildings will continuously transform how people carry out their activities on a daily basis. Furthermore, along with conserving energy, smart buildings will help to save money. Already some IoT smart building trends are taking shape to enable this transition.

A good example is how predictive maintenance will make use of sensors (IoT) and other hardware devices to get a report on the state of a commercial building and all equipment in it. This feedback will enable the timing of any necessary maintenance when it is needed, in a timely and effective manner. Unforeseen issues that usually crop up with a preventive maintenance schedule can be overcome by using a predictive maintenance approach.

Furthermore, worker productivity can be adversely affected by air quality. Industry research in this area has shown that workers are 10% more efficient in their duty when they work from buildings with good indoor environmental quality compared to more conventional buildings. Again, IoT devices can be used to measure and check the air quality, as well as carbon dioxide levels in the air using various sensors that are part of a mesh network. These devices are connected to all areas of the building infrastructure, thereby enabling a way to keep the environment and everyone in it healthy and productive.

Another new trend that is expected going forward is the use of IoT supported applications in smart buildings. A good example of this is the use of thermal imaging to allow facility managers to check if their equipment goes outside of its operating temperature range. This can be easily detected, thereby allowing maintenance to be performed before the equipment disrupts its normal operational mode. For example, IoT will transform the way commercial facility managers can track information and measure and collect data; this includes inaccessible areas that were previously too hard to reach. Installing sensors in various parts of the building will track all information that they never had access to in the past. By using IoT interconnected systems, facility managers will now have access to all pertinent information using these systems.

Furthermore, IoT will make it possible for commercial owners to have buildings that are energy sufficient. This influences the design of the buildings and allows them to be eco-friendly and resource efficient. Moreover, these intelligent building management systems can be remotely managed from anywhere, making it possible to replace outdated heavy construction equipment with sensors that can be controlled using indicators such as vibration and temperature fluctuations. Clearly, this saves a lot of energy and money while also reducing the maintenance costs.

Finally, one of the most important impacts that IoT can have on buildings is energy efficiency. Sensor networks help to provide information that helps managers control their assets more effectively, while also reducing harmful waste in the environment. Examples include:

• Using sensors for temperature control.

• Using actuators for HVAC controls.

• Complex applications like providing complete energy automation for a building.

• Considering weather forecasts to save real-time energy costs.

Wireless sensor nodes: An energy harvesting key application

A key application of energy harvesting systems is radio sensors in building automation systems. In the United States, buildings are the number one user of energy production on an annual basis, closely followed by the transportation and industrial segments.

A wireless network utilising an energy harvesting technique can link any number of sensors together in a building to reduce HVAC and electricity costs by adjusting the temperature or turning off lights to non-essential areas when the building or rooms within are unoccupied. Furthermore, the cost of energy harvesting electronics is often lower than running supply wires, or the routine maintenance required to replace batteries, so there is clearly an economic gain to be had by adopting a harvested power technique.

Nevertheless, many of the advantages of a wireless sensor network disappear if each node requires its own external power source. Even though ongoing power management developments have enabled electronic circuits to operate longer for a given power supply, this has its limitations, and power energy harvesting provides a complementary approach. Thus, energy harvesting is a means of powering wireless sensor nodes by converting local ambient energy into useable electrical energy.

Ambient energy sources include light, heat differentials, mechanical vibration, transmitted RF signals, or any source that can produce an electrical charge through a transducer. These energy sources are all around us and they can be converted into electrical energy by using a suitable transducer, such as a thermoelectric generator (TEG) for temperature differential, a piezoelectric element for vibration, a photovoltaic cell for sunlight (or indoor lighting), and even galvanic energy from moisture. These so-called ‘free’ energy sources can be used to autonomously power electronic components and systems.

With entirely wireless sensor nodes now capable of operating at microwatt average power levels, it is feasible to power them from non-traditional sources. This has led to energy harvesting, which provides the power to

charge, supplement, or replace batteries in systems where battery use is inconvenient, impractical, expensive, or dangerous. It can also eliminate the need for wires to carry power or to transmit data.

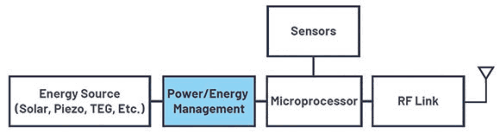

A typical energy harvesting configuration or wireless sensor node (WSN) is comprised of four blocks, as illustrated in Figure 1. These are:

• Ambient energy sources.

• A transducer element and a power conversion circuit to power downstream electronics.

• A sensing component that links the node to the physical world and a computing component consisting of a microprocessor or a microcontroller that processes measurement data and stores them in memory.

• A communication component consisting of a short-range radio for wireless communication with neighbouring nodes and the outside world.

Examples of ambient energy sources include TEGs (or thermopiles) attached to a heat-generating source such as HVAC ducts, or a piezoelectric transducer attached to a vibrating mechanical source such as a windowpane. In the case of a heat source, a compact thermoelectric device can convert small temperature differences into electrical energy. In the case where there are mechanical vibrations or strain, a piezoelectric device can be used to convert these into electrical energy.

Once the electrical energy has been produced, it can then be converted by an energy harvesting circuit and modified into a suitable form to power the downstream electronics. Thus, a microprocessor can wake up a sensor to take a reading or measurement, which can then be manipulated by an analog-to-digital converter (ADC) for transmission via an ultra-low-power wireless transceiver.

Of course, the energy provided by the energy harvesting source depends on how long the source is in operation. Therefore, the primary metric for comparison of scavenged sources is power density, not energy density. Energy harvesting is generally subject to low, variable, and unpredictable levels of available power so a hybrid structure that interfaces to the harvester and a secondary power reservoir is often used.

The harvester, due to its unlimited energy supply and deficiency in power, is the energy source of the system. The secondary power reservoir, either a battery or a capacitor, yields higher output power but stores less energy, supplying power when required but otherwise regularly receiving charge from the harvester. Thus, in situations when there is no ambient energy from which to harvest power, the secondary power reservoir must be used to power the WSN.

Successfully designing a completely self-contained wireless sensor system requires readily available power-saving microcontrollers and transducers that consume minimal electrical energy from low energy environments. Existing implementations of such energy harvester blocks are shown in Figure 1. These typically consist of low-performing discrete configurations, usually comprising 30 components or more. Such designs have low conversion efficiency and high quiescent currents. These deficiencies result in compromised performance in an end system.

Since high quiescent current limits how low the output of the energy harvesting source can be, it must first overcome the current level needed for its own operation before it can supply any excess power to the output. This is where Analog Devices’ Power by Linear (PbL) product offerings can bring a new level of performance and simplicity.

An energy harvesting example

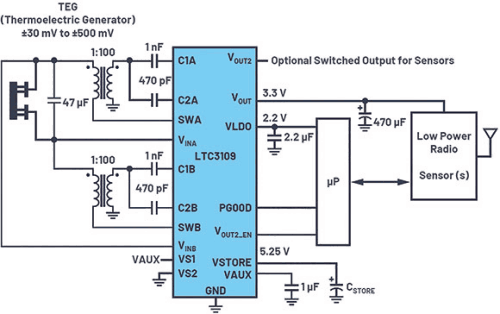

The LTC3109 is a highly integrated DC-to-DC converter and power manager. It can harvest and manage surplus energy from extremely

low input voltage sources such as TEGs, thermopiles, and even small solar cells. Its unique proprietary autopolarity topology allows it to operate from input sources as low as 30 mV, regardless of polarity.

The circuit in Figure 2 uses two compact step-up transformers to boost the input voltage source to the LTC3109, which then provides a complete power management solution for wireless sensing and data acquisition. It can harvest small temperature differences and generate system power instead of using traditional battery power.

The AC voltage produced on the secondary winding of each transformer is boosted and rectified using an external charge pump capacitor and the rectifiers internal to the LTC3109. This rectifier circuit feeds current into the VAUX pin, providing charge to the external VAUX capacitor and then the other outputs. The internal 2,2 V LDO regulator can support a low-power processor or other low-power ICs.

Conclusion

With analog switch-mode power supply design expertise in short supply around the globe, it has been difficult to design effective energy harvesting systems for use in green buildings. One of the primary hurdles has been power management aspects associated with remote wireless sensing.

Nevertheless, products like the LTC3109 can extract energy from almost any thermal source, thereby enabling a system designer to use an energy harvested power source. This not only reduces the use of fossil fuels but helps to make a greener building environment for current and future generations.

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved